Peak penetrant testing system performance is highly dependent on the integrity of the penetrant materials.

Although penetrants are carefully formulated to withstand the abuse and rigors of the industrial applications, any material is susceptible to contamination and degradation—and penetrant materials are no exception.

Causes of Liquid Penetrant Contamination

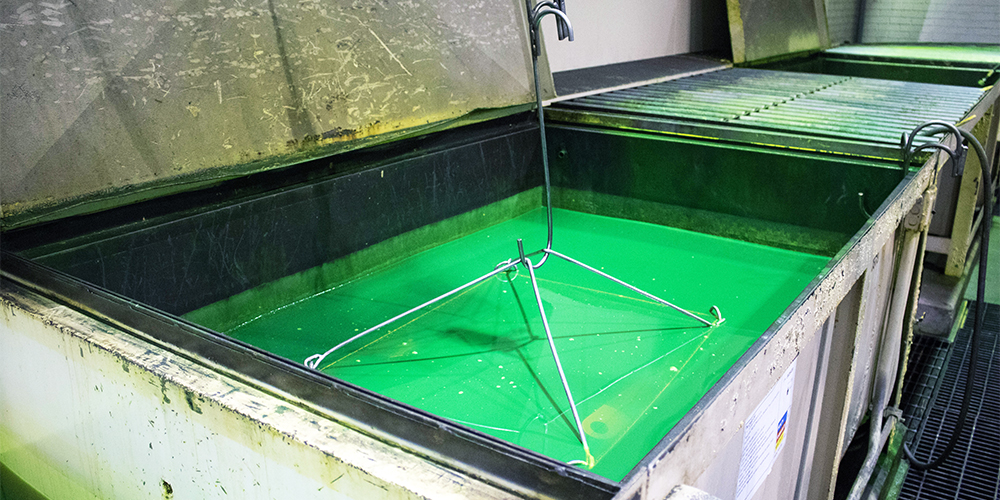

Some facilities apply penetrants on a one-time basis; others store penetrants in closed tanks or containers until used. However, most facilities use the immersion method, in which excess material is allowed to drain back after application to the part.

With the immersion method, tanks often are open to the environment, which increases the possibility of contamination. Used penetrants should be checked periodically for color or consistency changes to ensure acceptable performance for the inspection process.

Water

This is the most common contaminant and can result from careless rinsing, leakage from pipes or prewashed parts that are not fully dried. Water is not harmful until the water tolerance of the penetrant is met.

Dirt, soil and insoluble solids

Improper cleaning or allowing matter to fall into a tank can cause contamination.

Organic material

Oils, lubricants, paints, greases and organic solvents such as gasoline, cleaning solvents and degreasing fluid can cause contamination if not properly pre-cleaned. Although penetrants can absorb large amounts of oils and solvents, fluorescence will be decreased and washability will be affected.

Alkaline cleaners and acid

These are the most serious contaminants, alkaline cleaners and acid can destroy fluorescence upon contact. Also, some alkaline cleaners contain metasilicates, which can prevent penetrants from entering a crack.

Causes of Penetrant Degradation

Contamination isn't the only cause for penetrant performance to decrease over time, degradation can also play a role if you begin to see a decline in penetrant efficacy.

Heat

In some cases, heat can be used to speed up penetration. However, prolonged exposure to temperatures over 140°F (60°C) can reduce the fluorescence of penetrants. Temperatures over 250°F (121°C) will destroy fluorescence completely.

Evaporation

Penetrants stored in open tanks will undergo continuous evaporation, especially if they are stored in large tanks and exposed to warmer temperatures. Evaporation causes an increase in viscosity, which increases the dwell time, thus increasing labor time and inspection costs.

Faulty equipment

Un-calibrated or faulty equipment and accessories also can compromise penetrant systems. For example, drying oven thermostats or controls that are improperly set can lead to incorrect oven temperature readings. Also, water-pressure gauges can malfunction or output from black light bulbs can be reduced as bulbs age.

Effects of contamination and degradation will depend on the type and amount of contamination, but regular testing of penetrant materials is critical to finding problems and maintaining performance. Any changes in color, consistency or performance should be addressed immediately to ensure consistent, reliable inspection results.

Testing Options and Guidelines

Magnaflux recommends all users perform regular checks on in-use penetrants to comply with industry standards, ensure the conformance of penetrant materials and maintain the quality of penetrant system performance in aerospace inspections.

Regular testing also helps establish the point of performance loss and material failure.

Penetrant system testing can be performed in-house or through an external service. ASTM E1417 has established standards for performance checks for in-use materials.

Facilities which do not have the instrumentation or capacity required to perform testing on site can take advantage of Magnaflux PeneCert testing services for liquid penetrant, emulsifier and developers.

PeneCert uses state-of-the-art equipment to provide certification of compliance of in-use materials to various standards, testing is completed in just a few days and test results are emailed to the customer for immediate notification.