While additive manufacturing is not a new concept, in the last 10 years, additive manufacturing technology has advanced to the point where businesses of all sizes can consider and deploy additive manufacturing techniques.

But what is additive manufacturing? How does it work? What are the benefits and drawbacks? This blog provides a high-level overview of one of the manufacturing industry’s most prominent trends.

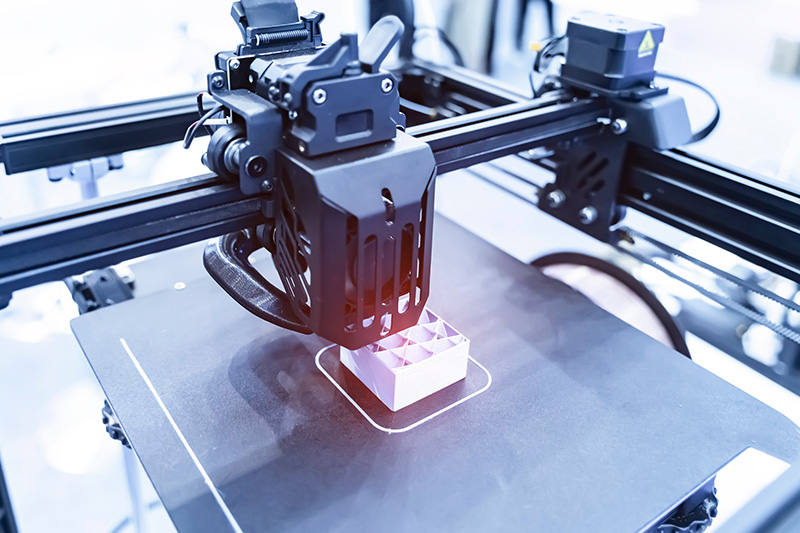

Additive manufacturing is a process in which individual parts or pieces are built layer by layer rather than machined or cast. In common parlance, this process is often referred to as “3D printing.” However, it can cover a wide range of methods that involve adding or altering material to create a desired object or adding material to an already completed part or object.

The difference between additive and traditional manufacturing techniques can be summarized in two simple words: addition and subtraction.

Traditional manufacturing is often “subtractive” in that the manufacturing process requires the removal of material to create the desired outcome.

In some cases that means that manufactured parts or components often require further machining after the part has been formed, which removes unnecessary materials or parts of the shape that were required during the production process but not needed in the final product.

In other cases, the traditional manufacturing process takes pieces of solid material, often metal, and carves the material into the desired shape usually using a computer numerical control (CNC) machine. A common example of this process is found in the automotive industry, where specialty manufacturers take large blocks of high-quality metal known as billet blocks and machine them into the desired shape by removing large amounts of material from the block.

In the additive manufacturing process, material is added in various ways during the production process. This method of manufacturing allows for objects and components of simple to complex geometry to be produced more efficiently than with previous manufacturing techniques. Additionally, by adding material, additive manufacturing techniques allow for the repair of already completed parts or components whereas in traditional manufacturing a damaged part would have to be completely replaced.

Additive manufacturing includes a wide variety of techniques and materials that range from highly complex industrial methods to desktop-sized 3D printers. The techniques detailed below are some of the most common methods used across numerous industries.

Binder jetting is an additive manufacturing process that takes materials including metals, sand, ceramics, and even composites in a powdered form and binds them together one layer at a time using a liquid binding agent.

Binder jetting is considered an efficient and cost-effective method as it doesn’t require large amounts of energy, offers quick production time, and leverages economical materials enabling simplified output scaling for organizations.

How Binder Jetting Works

The binder jetting process combines the steps of baking a layer cake and the technology of an inkjet printer. Within a binder jet machine, the build platform (where the parts are formed) is coated with the chosen material in a powder form. Then using a computer-aided design (CAD), the machine’s nozzle(s) deposits drops of the liquid binding agent along with coloring ink if the part requires it. Once the design layer has been completed, the build platform shifts downward based on a predetermined layer height value. The build platform is then coated again with more material power using what is known as a recoating blade and the process is repeated until the design is complete. Excess powder is then removed, and the part is either completed or moved on to the finishing stages depending on requirements and material type.

Solid-state cold spray is a low-temperature technique that takes material, commonly metal, and accelerates it through a focused nozzle along with blended gases onto a part. This process uses pressure and force to bind material together rather than heat or binding agents.

Solid-state cold spray differs from other techniques listed here in that it is often used to add additional material onto already completed parts rather than build new ones. This technique can be used in repairing in-service parts as it adds material to a part while also protecting a finished product that might be sensitive to high temperatures that are seen used in other types of additive manufacturing.

How Solid-State Cold Spray Works

Solid-state cold spray takes small particles of material and mixes them with carrier gases such as nitrogen and heats the particles to a malleable point (rather than their full melting point). The particles are then accelerated to high speeds and applied to a part or component. Once the material has been added, it is altered and modified to the required shape and strength requirements.

Directed Energy Deposition (DED) replies upon a focused energy source, commonly an electron beam, laser, or plasma arc within a nozzle which melts and deposits selected materials onto a substrate or an in-production part.

DED is a complex process, often requiring specialized chambers to increase effectiveness. However, it allows organizations to build or repair essential parts of multiple sizes, provides the ability to define the grain structure of a finished product, and enables the creation of multi-material components.

How Directed Energy Deposition Works

Guided by a CAD model, the DED process takes selected material, usually weldable metals or polymers, and melts them down within a nozzle. This nozzle then deposits the melted material onto the working surface where it cools and solidifies into a structure. The nozzle is often attached to a control arm which allows the nozzle to deposit material across multiple axes. The DED process is very similar to the way a hot glue gun melts a glue stick into a liquid form and pushes it through a nozzle.

Perhaps the most widespread and easily accessible of mainstream additive manufacturing techniques, material extrusion involves a heated nozzle placing melted material, typically polymers, which bond using chemicals or temperature adjustments one layer at a time onto a build space.

Material extrusion has the lowest entry barriers of the common additive manufacturing techniques in that materials and equipment are low-cost. Additionally, while this technique is not as precise or quick as others, it provides an easy way for organizations to build simple prototypes easily and efficiently.

How Material Extrusion Works

Material extrusion is a relatively simple process in which layers of heated material are added by a moving nozzle onto a build platform on which the layers of material fuse together until the designed object is complete. Typically, the nozzle moves horizontally while the build platform shifts vertically.

Powder bed fusion encompasses several subcategories which are based on the energy source (typically a laser or electron gun) and material types. This additive manufacturing technique is comparable to two of the previously mentioned sources. Powder bed fusion, like directed energy deposition, uses an energy source to bind materials together but the material is deposited on the build platform prior to the energy source being applied. Powder bed fusion works with the same general concept as binder jetting in that the selected material, which is always in powdered form, is placed on a build platform and joined in a specific pattern by a solidifying agent, in this case, an energy source rather than a liquid.

How Powder Bed Fusion Works

Powder bed fusion in practice is very similar to binder jetting. The build platform is coated with the chosen material in a powder form and a CAD design directs the energy source, usually a laser to bind the material together either by melting or sintering. Once the layer is complete, the build platform shifts downward and is then coated again with more material power, and the process is repeated until the part is completed.

Sheet lamination, sometimes referred to as ultrasonic consolidation, is a process in which many sheets of thin material are joined together using ultrasonic welding. Sheet lamination is a low-temperature technique used to join materials such as metal or polymers of different types, sizes, and colors to form a finished product which is then milled or shaped to a final product. Sheet lamination can offer an organization a large build surface and quicker production while limiting potential hazards or material damage that would occur with a higher temperature technique. However, there are often additional steps required after the layers are joined together.

How Sheet Lamination Works

Sheet lamination takes thin sheets of material onto a build surface and binds them together one layer at a time using ultrasonic welding which works by sending high-frequency vibrations onto a component which binds the materials together at a lower temperature than other technologies. Once all the layers have been joined, a part is then completed or moved to a finishing process in which excess or unnecessary material is removed and can often be reused in another lamination process.

Vat polymerization is an additive process that takes a liquified material, typically a polymer resin, and builds a component through a process called photopolymerization which uses a source of ultraviolet light to bind the resin together into a solid shape.

Vat polymerization is considered one of the first additive manufacturing techniques, dating back to the 1980s, and is seen as a cheap and effective way to build highly detailed parts quickly.

How Vat Polymerization Works

Like other techniques, vat polymerization works by taking a large amount of unaltered material and binding it together in some way. In this particular process, a build surface is plunged into a reservoir of liquified photopolymers, material that can be affected by ultraviolet light, and a UV light source is focused and adjusted in a controlled pattern that works layer by layer to build a solid structure. After each layer is built, the build surface is moved either further into the reservoir in a bottom-up build process where the light or heat source is below the material or further out of the reservoir in a top-down process where the surface is moved progressively layer by layer away from the binding tool. Once the part has been completed, the finished product is removed from the build sheet and any supporting structures or portions of the part used during the build process are removed.

Like any manufacturing technology or technique, additive manufacturing offers a range of benefits along with some drawbacks that need to be considered for any organization exploring additive manufacturing.

Additive manufacturing is a unique and potentially powerful tool for organizations of all sizes with multiple different techniques offering many options to choose from. Just like with any manufacturing technology, there are benefits and drawbacks that need to be evaluated by any business looking to implement these technologies. There is little doubt that many industries will likely see the expansion of additive manufacturing in their processes in the near future.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service