Liquid Penetrant Testing

Liquid Penetrant Testing Products

Please wait while we gather your results.

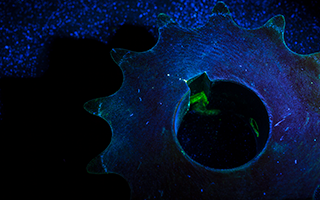

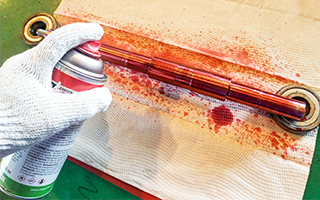

Penetrant testing applications, test pieces and UV lamps for LPI inspection

Fluorescent penetrants, visible / color-contrast dye penetrants, developers, emulsifiers and removers

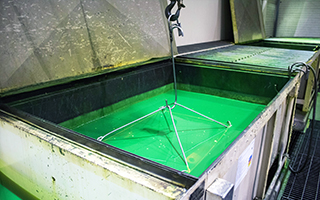

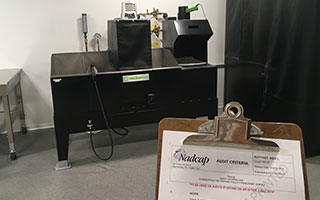

Penetrant testing equipment systems for water washable Method A and post emulsifiable Method B/D inspections

For in-use penetrant, emulsifiers and developers to ensure compliance to ASMT E1417 and AMS 2644

Please wait while we gather your results.

Learn More About Liquid Penetrant Testing

This technical paper shows examples of how Magnaflux can customize liquid penetrant equipment to meet part size and floor space requirements

We reveal common misperceptions about liquid penetrant inspection we’ve seen in the field in recent years

![The Ultimate Guide to Visible Dye Penetrant Testing [Video] The Ultimate Guide to Visible Dye Penetrant Testing [Video]](/Files/Images/Blog-Images/LPI-Infograpihc-Thumbnail_320x200px.png?Medium)

Some handy tips for beginners who are new to visible dye penetrant testing or NDT pros who want an easy reference guide.

Watch a demonstration of the penetrant inspection method according to ASTM E1417, including basic steps for NDT with an AMS 2644 Type 1 penetrant.

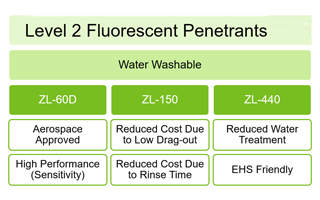

Understand fluorescent liquid penetrant sensitivity levels and how to find the right one for your application

The next revision of ASTM E1417 has been published, and a lot is changing. Here are several changes that you should be aware of.

Developers enhance the visibility of penetrant indications, in this blog we explore the various forms and learn what makes them different.

Learn how one engineering and fab company improved their NDT weld inspection quality with SKL-WP2 dye penetrant.

Learn about the Method D liquid penetrant inspection nondestructive testing method

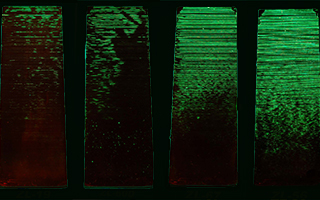

High quality fluorescent liquid penetrant inspections require strong removability combined with strong sensitivity to deliver clear, crisp indications

Learn how lower inspection temperatures affect the performance of dye penetrant testing cleaners, penetrant and developers

How perception and vision can have a significant impact on probability of detection in non-destructive testing inspections.

Learn how liquid penetrant testing products lose performance over time and what to do to ensure penetrant test reliability.

We highlight the 5 major sections to understand on a Safety Data Sheets (SDS) in accordance with US OHSHA Hazcom 2012 GHS regulations

Defining the different types of Level IIIs and some aspects of what their job entails

Learn more on why penetrant daily checks are important for the integrity of your LPI Systems

Learn about the separate category for Method A penetrants according to AMS 2644 and what they contain in their formula.

5-question guide to help understand the differences between Level 2 penetrants.

Read more about using penetrant testing products to inspect for leaks by using fluorescent or visible/colored penetrant to enhance visual detection of leaks.

Watch an overview of the dye penetrant testing method according to ASTM E1417, including basic steps for NDT with an AMS 2644 Type 2 penetrant.

Learn the differences between water-removable and non-water-washable liquid penetrant to figure out which is right for you

![What You Need to Start-up In-house Testing [Checklist] What You Need to Start-up In-house Testing [Checklist]](/Files/Images/Blog-Images/03162021-Titan-Thumbnail.jpg)

Step-by-step process listing everything from the equipment needed in magnetic particle testing and liquid penetrant testing to preparation for NDT audits

Answering popular questions regarding shelf life for magnetic particle and liquid penetrant products used in nondestructive testing

Secondary processing and finishing discontinuities are associated with the various finishing operations, after the part has been rough formed by rolling, forging, casting or welding.

When steel ingots are worked down into usable sizes and shapes such as billets and forging blanks, some inherent discontinuities may appear.

Service discontinuities are formed or produced after all fabrication has been completed and the part has gone into service.

While one might assume defects or abnormities occur during a part’s manufacturing process, there are some discontinuities which occur before a part’s creation even starts.

In the world of nondestructive testing, “defect” and its synonyms are not necessarily interchangeable.

As the NDT industry continues to modernize and evolve in the 21st century, sustainability has become a hot topic. For suppliers and consumers of NDT products, evaluating and adjusting processes and products, investing in innovative technologies, and putting sustainability at the forefront are critical.

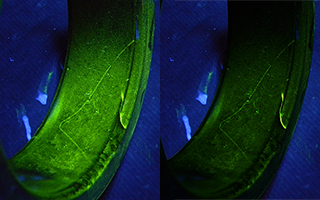

Learn how a automotive manufacturer increased indication detection in visible and UV light with developer.

![The Ultimate Guide to Fluorescent Penetrant Testing [Infographic] The Ultimate Guide to Fluorescent Penetrant Testing [Infographic]](/Files/Images/Blog-Images/01282020-Titan-Thumbnail.jpg)

Liquid penetrant inspection is a nondestructive test method which does not harm the parts being inspected.

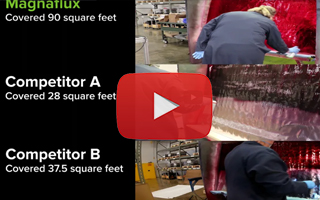

See how three popular visible liquid penetrants perform in a coverage test to learn how many square feet each can covered

![5 Things to Consider When Choosing a Mag Particle Yoke [Checklist] 5 Things to Consider When Choosing a Mag Particle Yoke [Checklist]](/Files/Images/Blog-Images/07232019-Titan-Thumbnail.jpg)

Safety is a make-or-break factor in a technician's world – we list details around hazards, storage, recycling, and shipping of NDT aerosols

On April 8, 2019 AMS 2644G1 was published, replacing the 2013 revision F. This revision was completed as part of a standard review cycle, and to address changes in the industry and shortcomings of the previous revision.

Learn about the available properties of developers and the relationship between dwell time and inspection quality

In this case study, we help an aerospace customer improve inspection quality and consistency with two Magnaflux penetrants

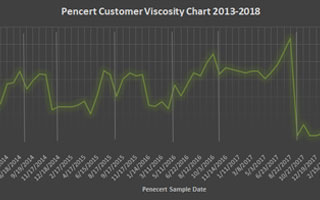

We show how a customer worked with the quality experts at Magnaflux to analyze data trends in the fluorescent penetrant to stay compliant

Liquid penetrant testing services help verify that your systems are compliant and act as a partner in your NDT process

Understanding ASTM and SAE/AMS specifications to select the corresponding Magnaflux product for Liquid Penetrant and Magnetic Particle Inspections

![Protective Armor Inspection with Zyglo Penetrant [Case Study] Protective Armor Inspection with Zyglo Penetrant [Case Study]](/Files/Images/Blog-Images/11272018-Titan-Thumbnail.jpg)

In this case study, we show how an armor solutions provider increased quality control on a semi-porous surface with ZL-19

Three steps to narrow down a penetrant method through governing specifications, part composition, and test parts

Properly demonstrating the system performance check was the #2 Nadcap audit finding for penetrant systems. What do you need to do to comply?

Learn more about test services for in-use penetrant, emulsifiers and developers to comply with ASMT E1417 and AMS 2644.

Learn the differences between type testing, batch testing and in-use testing for NDT liquid penetrants.

![Use of Solvent Based Developer for 3D Scanning [Case Study] Use of Solvent Based Developer for 3D Scanning [Case Study]](/Files/Images/Blog-Images/10202020-Titan-Thumbnail.jpg)

Learn about a customer who was in search of an aerosol with an even matte coating, fast drying properties, and easy is to remove

Learn how to look at the recommended actions associated with the chemical risk assessment.

Discover what mixing or testing could be required to return a penetrant to its original state once it has frozen

Learn how ISO 9001 affects the NDT materials you use, therefore affecting your quality management system