September 5, 2017

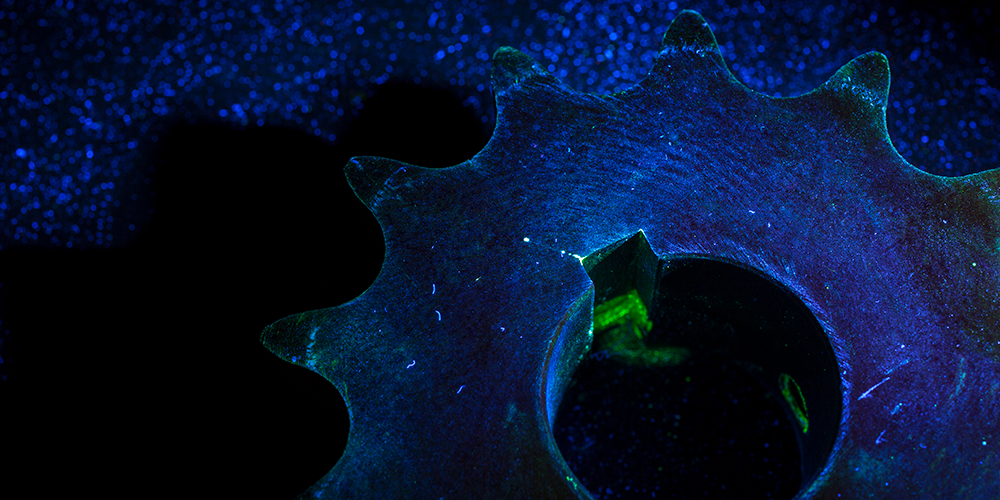

Our UK-based customer specializes in engine manufacture and refurbishment. They carry out liquid penetrant and magnetic particle inspection on high-performance engine components, including engine blocks, heads, pistons, rods, valves, crankshafts, camshafts and fly wheels. The end use of these components demand high-quality non-destructive inspection on a variety of different metals (steel, aluminum, magnesium, titanium) and 100% component inspection.

Due to the complexity of their product range, this customer needed a higher sensitivity penetrant than they were using, and it had to be of high quality and consistency to give them total piece of mind during inspection.

The challenge for our customer was two-fold:

In 2011 a new manager took over the running of this company’s inspection department. This manager has extensive experience in the aerospace industry and with using Magnaflux products, chosen for their quality, consistency and dependability.

Magnaflux worked with the new inspection department manager to:

By implementing working with Magnaflux to develop a solution which meet all their requirements, this customer achieved the quality reassurance they were looking for.

By changing and increasing their range of penetrant sensitivity levels, they were able to introduce real improvements within the refurbishment side of their business.

“Having been comfortable with using Magnaflux products for many years, I was very happy to be moving to using their products for both liquid penetrant and magnetic particle inspection once again. One thing that I have always been impressed with by Magnaflux is the quality of the whole package that you get from them – quality products through to quality Safety Data Sheets.

The ability to upgrade to using two penetrant sensitivities means that we now have the capability to cover both existing and future inspections.”

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service