November 13, 2017 | by David Geis, Product Manager, and Sakif Ferdous, Market Research Manager

Mercury-vapor lamps are the biggest culprits when it comes to inconsistent UV lighting. Whether you’re using a hand-held 100W lamp, a larger 400W HID fixture or even low-pressure fluorescent tube lighting, the intensity and coverage of the lamp can change dramatically throughout the day.

Not only do mercury-vapor lamps take time to warm up to full intensity, but any variation in the line voltage directly translates to a change in intensity. Power fluctuations can change from day to day, or even from shift to shift depending on what equipment is running in the plant.

Even with regular maintenance, the intensity of a particular lamp will fade over time as the bulb is used. An inspection booth with both stationary fixtures and hand-held lamps will have different coverage depending on the age of the individual bulbs and when they were last replaced.

The move from mercury-vapor lamps to LED UV lights helps to eliminate these kinds of variations, but swapping out existing lamps with LEDs can bring its own challenges.

Magnaflux is working with our customers to better understand the issues that end-users face. Below, we explain the challenges one aerospace OEM manufacturer faced, and how Magnaflux helped address their challenges.

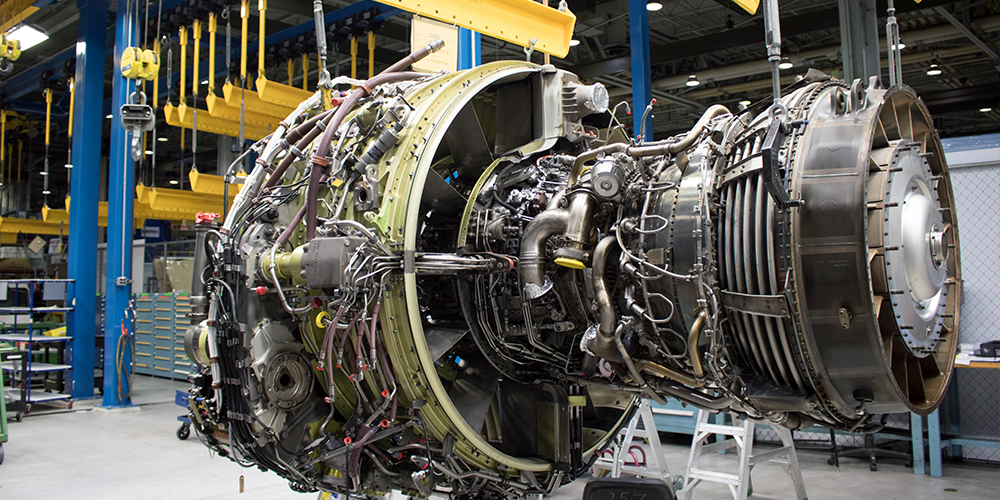

A mid-size aerospace OEM parts manufacturer performing fluorescent magnetic particle inspections.

Aerospace parts were inspected on a moving production line using HID mercury-vapor UV lamps mounted out of the way over the production line to give the inspectors enough room to work.

Even though the UV beam would cover the entire part, mounting the lamps overhead meant that the UV-A intensity was too low to consistently see indications.

Inspectors were forced to pick up each part to bring it closer to the lamp for inspection. This significantly slowed down the production line, and examination conditions varied from part to part.

ST700 stationary overhead LED UV lamps were installed to replace an HID lamp mounted above the production line. Magnaflux assisted the customer with installation and guidance in getting the best coverage and performance, in addition to helping update their control check procedures to comply with ASTM and Nadcap requirements.

The customer used the ST700 lamps in continuous production for 6 weeks to evaluate their performance in real-world settings.

The ST700 improved process control in for this manufacturer in key two ways.

First, parts did not need to be brought close to the lamp in order to find the “sweet spot” in the beam to find indications. This ensured that all parts received the same amount of UV intensity at the time of inspection.

Second, the inspection could be performed in a more natural position, reducing fatigue and stress on the inspector. The broad beam of the ST700 meant that the inspector could inspect the part closer to his/her body (instead of extending his/her arm to have the part centered under the light).

Coupled with the elimination of heat generated by the old 400W HID lamp, each part inspection was done faster, eliminating the production line bottleneck. “Seems like a winner to me. I know it’s a beta product at the moment, but I want another one for our new machine,” said the NDT supervisor.

Besides the main process-control improvements, the customer also found additional benefits were reported by the plant ES&H department. According to the customer, “the safety people are pleased with the idea of energy savings and hazardous waste reduction.” Using the ST700 can decrease power consumption in the inspection stations by over 80%, helping to meet plant goals for overall reduction of power consumption.

Swapping out mercury-vapor lamps with UV LED fixtures can present their own challenges, often trading off between intensity and beam area. The ST700 Stationary UV-A Lamp provides both high intensity and large beam area to address those challenges.

With the ST700, significant improvements can be made in the consistency and reliability of inspections, while increasing the safety and ergonomics of the system as a whole.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service