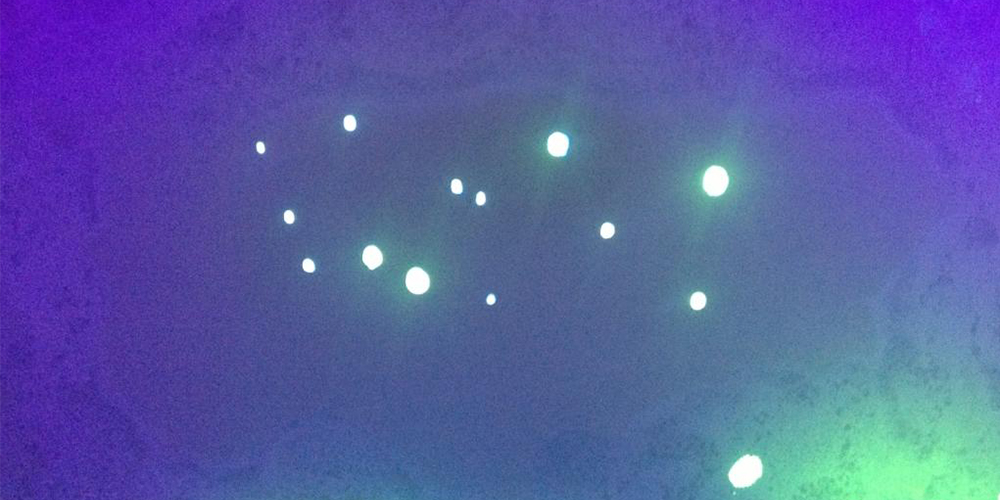

ZYGLO® ZL-60C penetrant applied, but with no developer.

Our customer is a manufacturer of heat exchangers for the automotive sector. The use of heat exchangers in a vehicle range from engine and oil cooling to air conditioning. In this case, they wished to inspect an aluminum plate used for radiator assemblies. As a non-ferrous metal, the most appropriate method for the detection of faults is liquid penetrant inspection.

Specifically, our customer had concerns about tiny holes – caused by corrosion – that penetrated through the aluminum plate. This corrosion presented the opportunity for leaks, particularly when the plate was used at high temperatures.

Magnaflux penetrants – both visible and fluorescent – are widely used for the detection of surface-breaking defects. Where the defects are particularly small, the use of a penetrant alone can make them difficult to see with the naked eye.

The purpose of a developer is to effectively pull the penetrant back out of a defect to allow it to be seen by an inspector. The action of pulling it back to the surface also allows the penetrant to spread along the surface around the defect, thus magnifying the strength of the indication.

With UV fluorescent penetrants, the developer particles both reflect and refract the UV light, which make the indications brighter. With visible penetrants, the developer, in addition to pulling the penetrant back to the surface, creates a white background to form an ideal contrast between the indication and the surrounding area.

Under AMS 2644, there are four primary classifications of developer, namely:

Dry powder developers

Dry powder developers (ZYGLO® ZP-4D) are generally considered to be the least sensitive. However, they are easy to use and inexpensive. They can be applied using the following techniques:

Water suspendable developers

With a water suspendable developer (ZYGLO® ZP-5B), the developer particles suspend in water. It is important to keep the developer suspension stirred or agitated to prevent the particles from settling out of the suspension. After application of the developer, you will need to dry the parts to remove excess water. Water suspendable developers can be applied using spray, immersion dip or flow on techniques.

Water-soluble developers

With a water-soluble developer (ZYGLO® ZP-14A), the developer particles dissolve within a water carrier. After application, a film of developer forms on the surface of the part during the drying stage. Water-soluble developers can be applied using spray, immersion dip or flow on techniques.

Non-aqueous developers

Non-aqueous developers suspend in a solvent-based carrier. There is no need for force drying as the solvent evaporates quickly from the part.

In general, non-aqueous developers are supplied and used as aerosols for convenience and ease of use. If used in bulk, they will need to be applied using a spray gun, with care being taken to keep the developer stirred/agitated.

Magnaflux offers developers with different solvent make-ups to meet the requirements of our customers:

In this case, our customer wanted to use an aerosol-based fast-drying penetrant. For this inspection, the client chose to use SPOTCHECK® SKD-S2, which is an isopropanol/acetone-based developer.

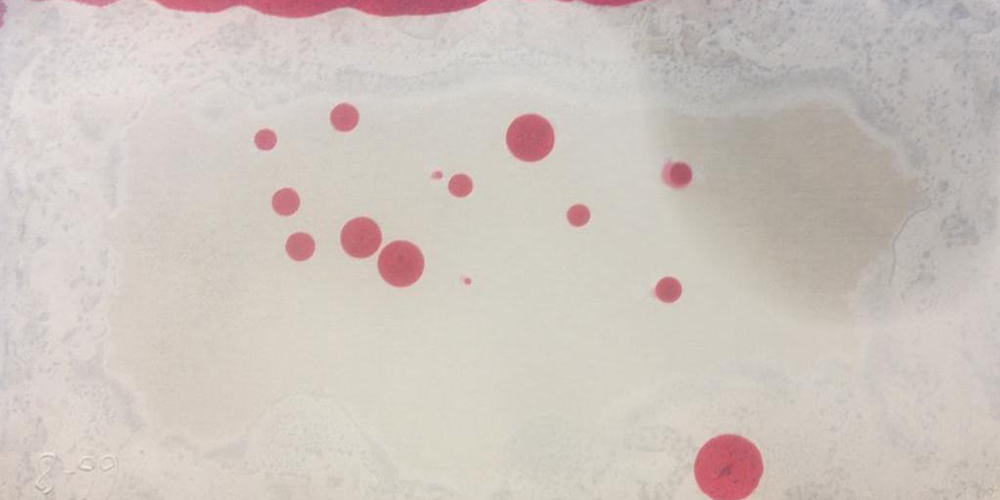

The results of the evaluation carried out by our customer are shown pictorially below. What can be seen from this evaluation is the powerful effect of using a developer with both a fluorescent and visible penetrant. Over the first ten minutes, what were small indications of surface-breaking defects were transformed so they can be easily identified by the naked eye under either UV or visible light.

ZYGLO® ZL-60C penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 2 minutes.

ZYGLO® ZL-60C penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 2 minutes.

ZYGLO® ZL-60C penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 10 minutes.

ZYGLO® ZL-60C penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 10 minutes.

SPOTCHECK® SKL-WP2 penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 10 minutes.

SPOTCHECK® SKL-WP2 penetrant and SPOTCHECK® SKD-S2 developer applied for ca. 10 minutes.

February 6, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service