By Shawn Kilty, Division R&D Manager

One significant change in Revision G is the inclusion of a new class of penetrants, Method A(W). Method A(W) was created to distinguish between Method A penetrants that are water-based, and those that are oil or surfactant based. Previously, all Method A materials were lumped together, regardless of their chemical composition. This change was made to address the increased interest in the market for products that are water-based. Method A(W) penetrants are being defined as products that contain 20% or more water.

Additional changes were made to support the addition of Method A(W) to the specification, including:

The next big update in Revision G is a significant change to the qualification criteria for Method A penetrants. Since its inception in 1996, the qualification criteria for AMS 2644 have undergone several changes as the lab at Wright-Patterson AFB improved the techniques used to test and approve penetrants. Although the qualification criteria changed, previously approved products were never required to be retested. This practice led to a situation where at least some of the penetrants listed on the Qualified Products List (QPL) would not meet the most current qualification criteria.

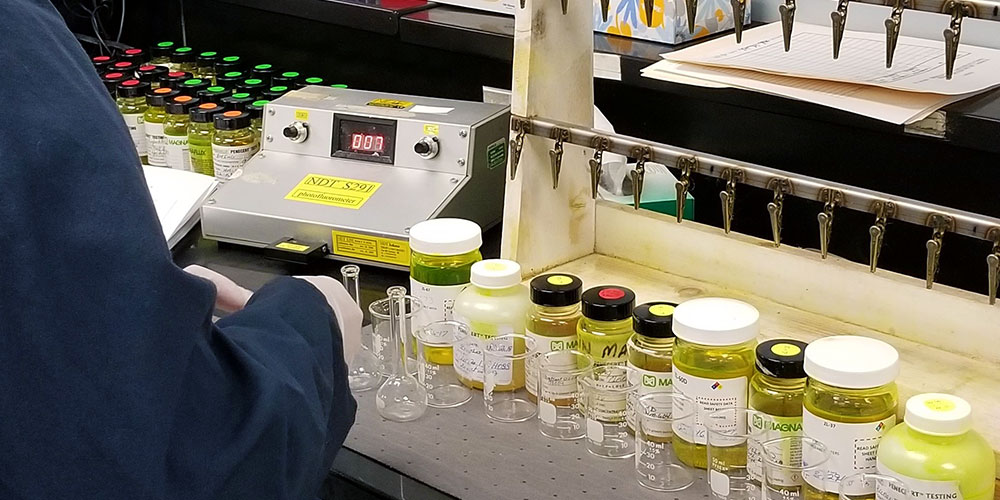

To address this, penetrant manufacturers were required to submit samples of all Method A penetrants to WPAFB. These penetrants were tested for sensitivity and removability, and new standards were designated to establish the minimum sensitivity and removability requirements for each sensitivity level. Method A(W) penetrants were also tested as part of this process, and they will be held to the same standards as the Method A materials.

Another significant update to revision G is a requirement for penetrant manufacturers to provide data demonstrating that their products are consistent between their manufacturing facilities. Only one sample from a single facility undergoes testing during the qualification process, causing a concern that individual products may vary significantly from one facility to another. To address this, supporting data should include material scans using either Fourier Transform Infrared Spectroscopy (FTIR) or Mass Spectroscopy (MS). The new requirement helps ensure manufacturers are providing products that are consistent across all manufacturing sites.

Work has already begun to collect data for the next revision of AMS 2644. The plan is to have updated qualification criteria for Method B systems included in this revision. This update will be similar to the update to the Method A qualification criteria discussed above. WPAFB requested that manufacturers submit samples of all Method B materials by mid-March, 2019. No timetable is set for completion of this testing.

Published May 21, 2019

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service