By Michael Giannini, Business Development Manager

Magnaflux offers custom Liquid Penetrant Equipment to address many of our customer’s unique needs. In the past, we have taken upon large and small projects that got us to put our creative hats on in order to provide customers with smart solutions for their inspection needs. Below are two examples that highlight our commitment to tackling LPI equipment challenges.

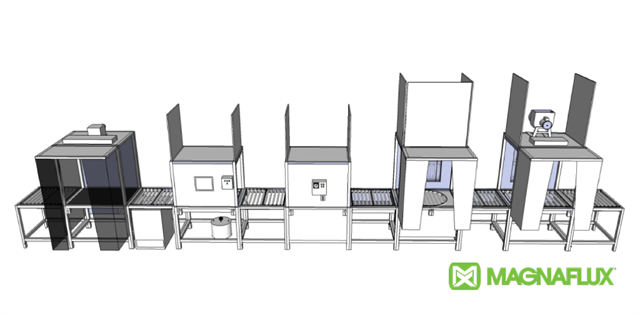

The system shown in the drawing below is designed to process a variety of small airframe components. The outside dimensions of most components in this system are 40” X 65”, and were sized to accept the largest part that the customer would need to process. The unit includes a lowerator in the penetrant dip tank, holding tanks for clean and dirty water, a pressure pot which delivers dry developer, and a dust collector to evacuate developer from the developer station.

Parts are loaded and unloaded using customer supplied hoists, Magnaflux worked with the customer to design a special system that could fit into a limited room space.

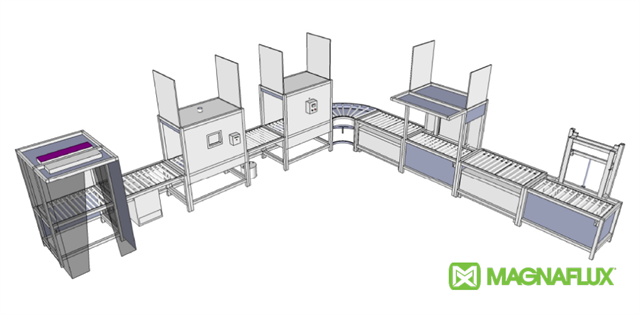

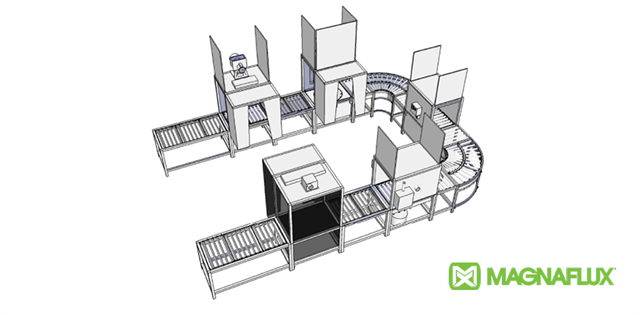

This aerospace components manufacturer needed several cells that were built using the same processing components, but due to space constraints each cell had to be configured differently. The first system was configured in a U shape, the second was in a straight line, and the third was in an L form. In other systems we have changed the roller table length to accommodate different space requirements.

These systems use automatic spray booths to apply penetrant and include automatic spray wash stations. Both the penetrant and wash stations include mist collectors to contain fluids, and there is a collection tank for rinse water. The operating stations in these systems are 36” X 48” in dimension.

Magnaflux can custom design penetrant equipment to meet a variety of part sizes, space, and handling requirements, as well as supply monorails and overhead conveying systems as needed.

Our Engineering team loves a challenge! Call us if you want to brainstorm ideas together, or get a jump start by filling out our Penetrant Testing Equipment Checklist.

Published May 1, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service