By David Geis, Product Manager

LED lamps and other electronic devices are frequently advertised with an IP rating. In this context, "IP" stands for Ingress Protection and refers to the environmental conditions the equipment is designed to handle. What does that mean for us testing in the real world?

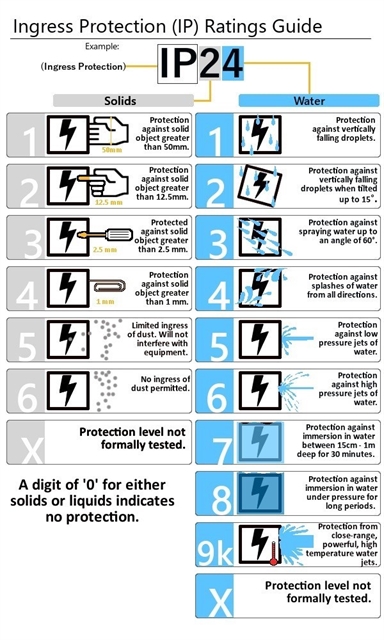

IP ratings are defined by ANSI/IEC 60529, the Ingress Protection Code. The first digit is the degree of protection against solids, particulate, and dust. A rating of 0 represents no protection, higher numbers mean higher protection, topping out at dust-tight with a rating of 6.

The second digit is the degree of protection against water and other liquids. Again, a rating of 0 represents no protection, and again protection increases with the numbers, with 8 representing submersion deeper than 3 ft / 1 m.

The rating system was initially designed as a way to classify electrical enclosures. Today, it is used by engineers and technicians as a standard way to develop a product to a specific sealing requirement. The chart below can be used to help visually describe what each rating step means. The rating system can be found throughout a multitude of industries; for this article, we will focus on the kind of conditions expected during magnetic particle and penetrant testing.

Magnetic Particle Inspection can be performed with either dry or wet materials. Dry magnetic powders have a range of sizes and sensitivities, but as far as the IP Code is concerned, they would all be classified as "dust" smaller than 1 mm. Dry powders are typically used with electromagnetic yokes, so the yoke must be protected against both the environment and the magnetic particles used for inspection. A rating of 5 would mean the yoke is not 100% dust-tight, but anything that does get inside will not interfere with the operation of the device. A rating of 6 would be dust-tight, so long as the housing seals are intact.

Wet Magnetic Particle adds liquid protection to the mix. Liquid carriers could be either oil-based or water-based, with either fluorescent or visible particles in suspension. With bulk materials, the part is flooded with bath at very low pressure to allow particles some mobility without being washed away. That would correspond to a liquid protection rating of 4, since some of the bath may splash onto the yoke or other device. NDT Aerosols are a bit harder to classify because, while they provide a low-pressure spray (liquid rating 5), the volume is rather small, and the spray is not directed at the yoke (liquid rating 4).

Penetrant inspection has a mixture of conditions depending on the Method and Form of materials. Methods A, B, and D penetrants require significant water rinsing, and low-pressure spray is typical.

UV lamps used to check penetrant coverage and rinse should have a liquid rating of at least 5. High-pressure jets (rating 6) may be present while cleaning parts, and immersion (rating 7-8) is a common method for penetrant application and removal. UV lamps are generally not used in those conditions, so they would not themselves see pressurized jets or immersion. While UV lamps are not commonly used in the developer station, Form (a) dry powder developers are very common, so a solids protection rating of 5 or 6 would be appropriate. Of course, the inspection booth is where UV lamps are most used, but no inspection materials are applied there.

Environmental conditions also play a factor in equipment protection. However, even during field inspection, far more powders and liquids are used for the MT or PT process itself compared to the environmental dirt, dust, or rain a yoke or UV lamp will encounter.

The materials used in Magnaflux products such as housings, gaskets and seals, optics, and power cords are all tested to be compatible with penetrants, emulsifiers, developers, carrier oils, cleaner/removers, and alkaline cleaning solutions.

For portable equipment like yokes and UV lamps, Magnaflux verifies the design with thorough testing at a Nationally Registered Testing Lab to confirm IP dust and liquid protection ratings. For example, the Y-2 AC Yoke was tested and verified to IP54, while UV lamps like the EV6000, EV6500, and ST700 were tested and verified to IP65.

Published June 23, 2020

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service