By David Geis, Accessory Product Manager

NRTL stands for Nationally Recognized Testing Laboratory. There are many labs, some more familiar to the public than others. For the United States, OHSA maintains a list of approved labs for product evaluation and compliance certification.

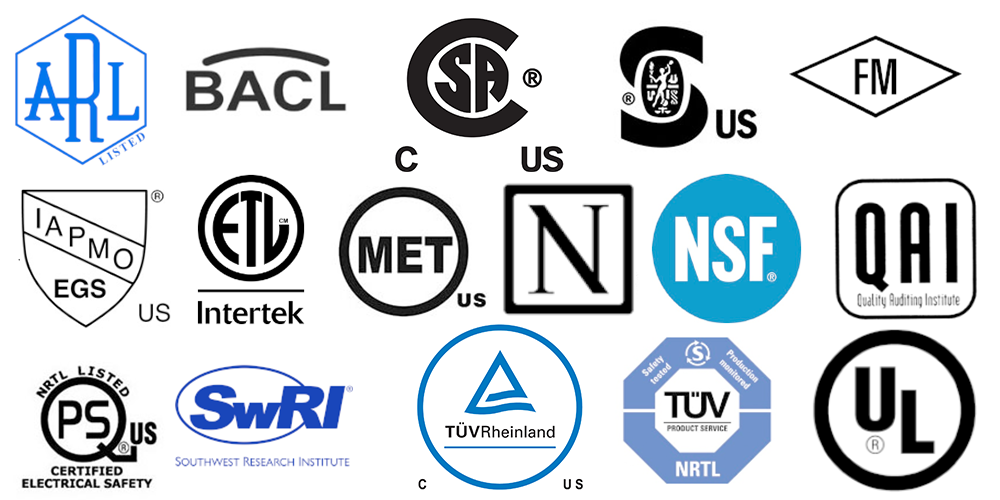

These laboratories have the facilities to test and certify equipment to US and Canada safety regulations. Different facilities are recognized for certifying to different regulations, from electrical safety to electromagnetic compliance, pressure and leak testing to explosion-proof ratings for hazardous locations. Each lab has its own unique symbol, but because they all test to the same C-US standards, the certifications are equivalent.

For equipment used in Penetrant and Magnetic Particle testing, electrical safety compliance is the primary concern. Both testing methods use water-based and oil-based materials with electrical equipment, so adequate grounding and safety measures must be in place to protect the operators and inspectors.

Safety certification can take several forms. For small equipment like UV LED lamps or electromagnetic yokes, models can be submitted to an NRTL for testing and evaluation. This process can take several months to complete, requiring both technical and quality system audits of the manufacturing facilities. But once the process is complete, the product can carry an NRTL symbol demonstrating the model is safe for use.

One example of model certification would be our EV6000 UV LED lamp. Magnaflux has completed the process through TUV Rheinland of North America, certifying the EV6000 to American and Canadian electrical safety standards. This enables the EV6000 to carry a cTUVus mark, signifying compliance.

On the other hand, large-scale capital equipment does not lend itself easily to model certification. Beyond the cost involved, the equipment may be customized to fit a specific user’s MPI or FPI application while model certification must cover all possible configurations. In those cases, individual equipment can be audited and certified by an NRTL agent. These individual site certifications are faster and less complicated than model certifications, but they only apply to a specific piece of equipment. Individual NRTL certifications may be added to Magnaflux standard and custom Magnetic Particle and Penetrant Equipment as required for specific projects. Please contact us for more information and a project quotation.

|

Symbol |

NRTL |

Location |

|---|---|---|

|

|

Applied Research Laboratories of South Florida |

Miami, FL, USA |

|

|

Bay Area Compliance Laboratories |

Sunnyvale, CA, USA |

|

|

CSA Group Testing and Certification |

Etobicoke, ON, Canada |

|

|

Curtis-Straus |

Littleton, MA, USA |

|

|

FM Approvals |

Norwood, MA, USA |

|

|

International Association of Plumbing and Mechanical Officials EGS |

Ontario, CA, USA |

|

|

Intertek Testing Services NA |

Arlington Heights, IL, USA |

|

|

MET Laboratories |

Baltimore, MD, USA |

|

|

Nemco North America |

Carlsbad, CA, USA |

|

|

NSF International |

Ann Arbor, MI, USA |

|

|

QAI Laboratories |

Burnaby, BC, Canada |

|

|

QPS Evaluation Services |

Toronto, ON, Canada |

|

|

SGS North America |

Suwanee, GA, USA |

|

|

Southwest Research Institute |

San Antonio, TX, USA |

|

|

TUV Rheinland of North America TUV Rheinland PTL |

Newton, CT, USA Tempe, AZ, USA |

|

|

TÜV SÜD America TÜV SÜD Product Services |

Peabody, MA, USA Munich, Germany |

|

|

Underwriters Laboratories |

Northbrook, IL, USA |

Published April 2, 2019

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service