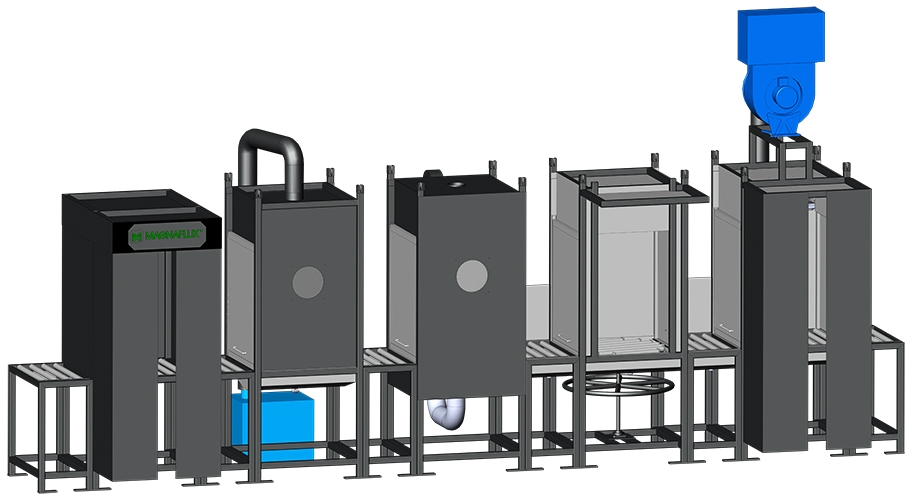

Magnaflux’s modular penetrant equipment design makes it simple and cost-effective to build the right equipment for every process, including water wash, lipophilic and hydrophilic LPI testing, while also conforming easily to fit the required work flow and available floor space with straight line, U-shaped and L-shaped designs.

Durable, industrial-duty construction will stand up to years of heavy daily use in demanding NDT environments with minimal maintenance or down-time.

For additional information on Magnaflux modular penetrant equipment, submit a Custom Equipment Inquiry.

Easily conforms to fit to the necessary work flow and available floor space with straight line, U-shaped and L-shaped designs

Ergonomic conveyor rollers allow operators to effortlessly and quickly move parts through the system

Multiple penetrant application methods, including dip or conventional spray, for added process changeability

Optional Power Immersion automatically raises & lowers parts for better operator ergonomics, especially with heavy parts

Optional Split Roof can accommodate overhead crane for part handling

Optional Counterbalanced Manual Doors available instead of curtains

Modular design makes it simple and cost-effective to build the right equipment for every process, including water wash, lipophilic and hydrophilic

Durable stainless steel tanks will stand up to demanding NDT environments with minimal maintenance or down-time

Dynamic Cloud Developer Station increases through-put by eliminating the need for maintenance checks

Energy efficient Dryer Station

Calibrate the Rinse Station quickly and meet ASTM and Nadcap requirements with quick-disconnect gauges

Front-mounted port on Dryer Station makes calibration fast and simple

Penetrant Dip Tank

Penetrant Spray

Drain

Emulsifier Dip Tank

Rinse Spray

Dryer

Dynamic Cloud Developer

Rest

Inspection Booth

Outside Dimensions: 38 x 42 x 73 in / 97 x 107 x 185 cm

Outside Dimensions: 36 x 70 x 142 in / 91 x 178 x 361 cm

Outside Dimensions: 36 x 36 x 36 in / 91 x 91 x 91 cm

Outside Dimensions: 38 x 42 x 73 in / 97 x 150 x 241 cm

Outside Dimensions: 36 x 59 x 95 in / 91 x 150 x 241 cm

Outside Dimensions: 36 x 50 x 95 in / 91 x 127 x 241 cm

Outside Dimensions: 36 x 36 x 95 in / 91 x 91 x 241 cm

Outside Dimensions: 36 x 36 x 36 in / 91 x 91 x 91 cm

Outside Dimensions: 36 x 59 x 91 in / 91 x 150 x 231 cm

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service