By David Geis, Product Manager

Whether you are in the automotive or aerospace industry, system performance checks are crucial for an optimal inspection. A system performance check needs to be run daily to validate the capability of the system to magnetize and create indications for examination. A standardized test piece, an example part with known defects, or a part with artificial defects attached to it, all can be used to perform the system performance check. Details of the procedure vary with the type and configuration of equipment being used.

The tool steel ring is a standardized test piece commonly used with wet bench magnetic particle equipment. The ring is machined from AISO O1 tool steel, annealed, tested and certified to meet AS 5282 specifications. Typically used with a ½ inch (1 cm) central conductor, the tool steel ring has 12 machined holes at increasing depths from the edge and is used to verify the performance of HWDC, FWDC, and 3-phase FWDC magnetizing equipment. Suitable for use with wet or dry materials and visible or fluorescent particles. The number of indications required depends on the waveform and magnetizing current amperage (refer to ASTM E1444 or E3024 for more information).

The MPI test bar is a standardized test piece that can be used with wet bench magnetic particle equipment, power pack coil wraps, or magnetic yokes. The test bar has both surface and sub-surface flaws for use with AC, HWDC, FWDC, and 3-phase FWDC magnetizing equipment. Surface EDM notches in two directions allows the test bar to be used to confirm both circular (head-shot) and longitudinal (coil-shot) magnetization.

Learn about quantitative quality indicators in our blog Breaking Down How to Use Magnetic Flux Indicators and QQIs.

See quantitative quality indicators (QQI) in action, including basic steps to test for artificial defects and verify field direction and relative strength in our Overview of Quantitative Quality Indicator Test Pieces for Magnetic Particle Inspection video.

For a valid magnetic particle inspection, sufficient magnetic field must be applied to the part to magnetize the area being examined. Although the magnetic field within the part cannot be measured directly, several accessories are available to confirm that sufficient magnetic field is present. Meters and gauges may also be used to confirm the level of demagnetization after inspection is completed.

The Hall Effect Meter is a calibrated digital meter for measuring the strength of an applied magnetic field. A calibrated sensor probe is placed normal to the surface being examined and responds to the magnetic field tangential to that surface. The meter then provides a reading of the field strength in Gauss, Tesla, or amp/meters, accurate to +/-3%. The Hall Effect Meter has multiple functions, including AC (RMS) and DC (Peak) modes, auto-range and auto-zero, and Min/Max/Peak hold.

Learn about the demagnetization units for Magnetic Particle Inspection and see a demonstration of field indicators in our Demagnetizing Techniques for Magnetic Particle Inspection video.

Magnetic field gauges are portable analog gauges commonly used to quickly check for magnetization or demagnetization levels. Available in multiple ranges, a calibrated field gauge responds to the inherent or retained magnetic field within a part, accurate to +/-5%. Non-calibrated field gauges are also available as a quick go / no-go check for whether a part is magnetized or if it has been demagnetized.

Magnetic fields are directional in nature, and only discontinuities that are orthogonal to the lines of flux will induce leakage fields and form magnetic particle indications. The direction of the magnetic flux is just as important as the strength of the applied magnetic field. Several accessories are available to verify the direction of the magnetic flux within a part under test.

Learn about laminated flux strips in our blog Breaking Down How to Use Magnetic Flux Indicators and QQIs.

The pie gauge is a tool for quickly verifying the direction of magnetic flux on a surface. It is made from eight ferrous segments, braised into a single piece, providing a star pattern of non-ferrous discontinuities. Typically used with dry powders for yoke inspection, the pie gauge can be held at any angle and will generate indications perpendicular to the direction of the magnetic flux. A similar test gauge, the Berthold Penetrameter, is commonly used in Europe. The Berthold Penetrameter uses four instead of eight ferrous sections, but it is used the same way as the pie gauge. While these devices are useful for checking the direction of magnetic flux, they are not considered adequate for demonstrating magnetic field strength.

When using wet materials, the concentration of magnetic particles in the liquid vehicle must be maintained at the right levels to create indications. Different accessories are used to measure the concentration depending on the type of magnetic particles being used.

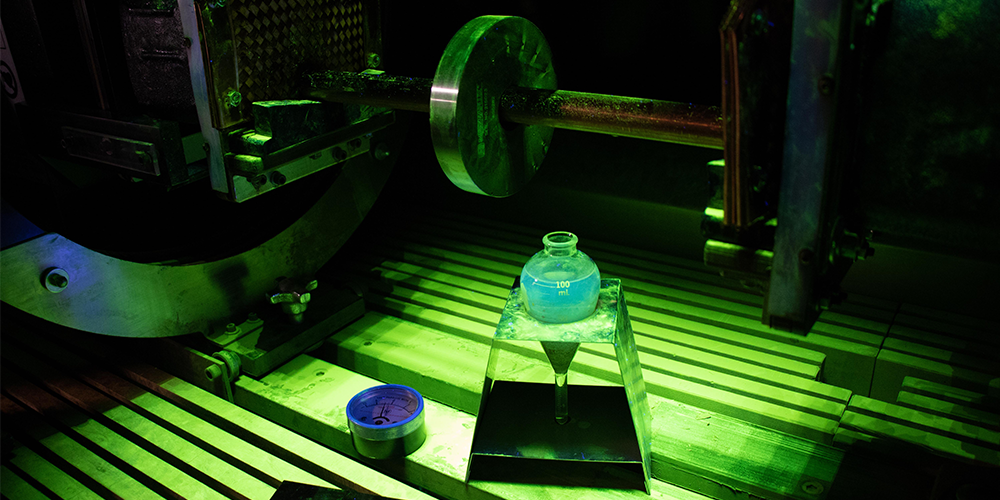

When using wet method materials – either water or oil – the ability to form clear indications is directly related to the concentration of magnetic particles. Different types of particles are effective at different concentration ranges. The magnetic particle centrifuge tube, also known as a Goetz tube, provides a means of verifying the particle concentration as well as evaluating the carrier quality and level of contamination present. The tube is filled with agitated solution and set aside for at least 30 minutes to allow particles to settle. The concentration of particles can then be read from the markings on the tube. Sediment layers from contamination can also be observed, as well as the clarity of the liquid vehicle. High levels of contamination or haziness in the liquid will increase background, decrease contrast, and degrade the quality of magnetic particle examinations.

Published August 21, 2018

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service