As machines age and the contactors heat up, the magnetizing amperage degrades, becoming more unreliable and inconsistent. These unpredictable electronics have been discontinued at Magnaflux and are no longer serviceable.

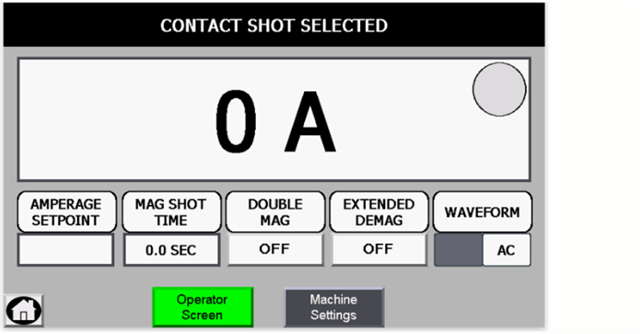

The latest Magnaflux MPI wet benches now include Allen-Bradley PLC-controlled interface and TrueAmps technology, allowing the customer to dial in the exact amperage they need to test the part properly. Magnaflux developed TrueAmps through customer feedback to quickly set up various parts when simply typing in the amperage. In contrast, before, technicians would have to test the mag shot multiple times before testing the part to confirm they had the correct range of amperage. Accuracy in amperage can reduce the risk of damage to a part, such as arching or increasing part temperature.

If complying with NADCAP or ASTM E-1444-21, the first mag shot will create a baseline and must be within +/- 10% or 50 amps repeatability.

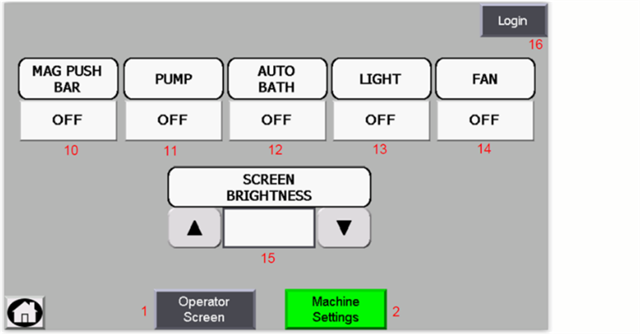

Old machines only had buttons, ammeters, and dials. Machines produced today are digitally Allen-Bradley PLC-controlled to reduce guesswork and ease-of-use touch screen.

A global service center network is available for maintenance, calibrations, repairs, and education for every purchased piece of MPI equipment.

Magnaflux no longer supports equipment (made before 2000) due to the unavailability of service parts. The likelihood of a component failure within older equipment may render the machine unusable, resulting in production downtime.

MPI equipment now offers a database system option to improve NDT process control and efficiency by providing traceability, 1,000 programmable techniques, and an integrated barcode scanner. Operators must review the concentration, light meter readings, and daily checks recorded in the database for their records. Previously shipped machines cannot be retrofitted with this option.

Magnaflux has worked with multiple Level 3’s going through NADCAP audits and has successfully resolved any NADCAP auditor questions or concerns.

Published April 26, 2022

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service