October 24, 2017

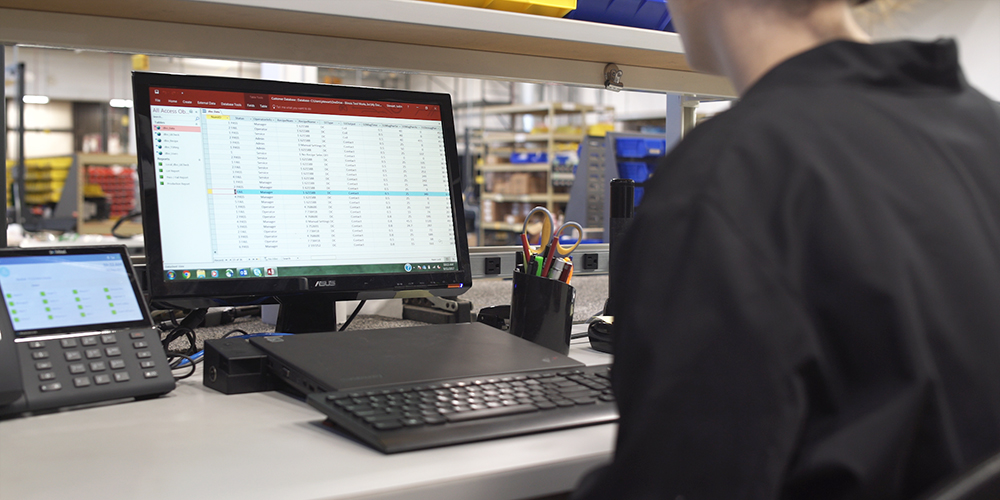

The Database System for Magnaflux wet bench machines improves NDT process control and efficiency by providing traceability for parts, jobs, customers, operators, and more.

Multiple levels of user-controlled access and 100 programmable operator profiles ensure consistency and prevent accidental modifications, ideal for locations with multiple operators and various levels of experience.

The integrated barcode scanner speeds up inspections and minimizes errors by reducing manual data entry, such as part selection and test parameter settings.

Switching between jobs is fast and easy with the barcode scanner since new test parameters are automatically set when the operator scans in the next job.

Electronic database tracking reduces the need for operators to manually record inspection data.

The Database System automatically compiles all test information in a Microsoft SQL database, for advanced quality control tracking and reporting options.

Electronic reporting reduces dependency on manual recording keeping for safer, more reliable trackability of Nadcap audit criteria and other compliance requirements.

The Database System will take your NDT quality to the next level, while saving time and increasing through-put.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service