by Cheri Stockhausen, Product Applications Manager

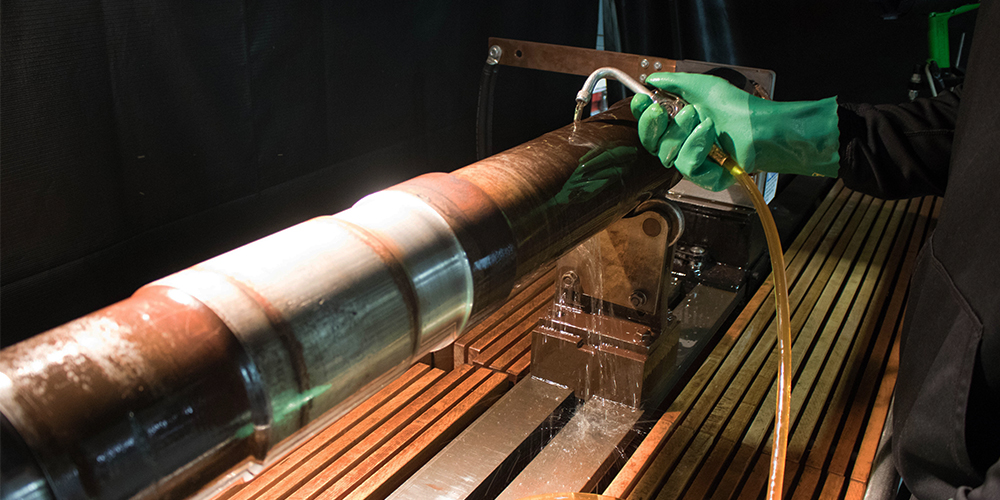

It is generally accepted that fluorescent magnetic particles are an important component for a critical magnetic particle inspection. However, the importance of the carrier oil is often minimized.

Let’s consider why the carrier oil is also an important part of the magnetic particle inspection and which characteristics are critical when choosing a carrier oil.

Proper viscosity of the carrier oil promotes efficient magnetic particle mobility, stability, and suspension for reliable inspections.

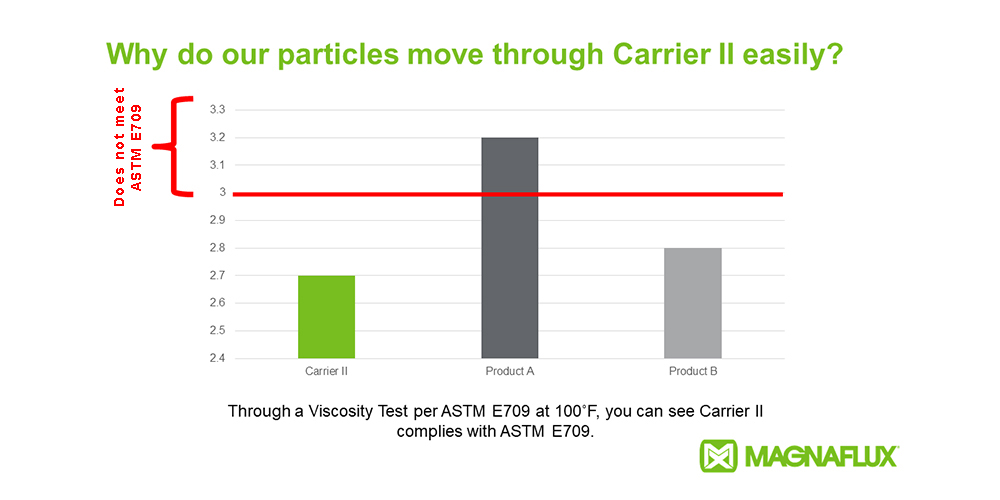

With the proper viscosity, magnetic particles efficiently flow and identify indications. Per ASTM E709 Standard Guide for Magnetic Particle Testing, the viscosity of an NDT approved carrier vehicle should not be higher than 3.0 cSt at 100°F / 38°C and not more than 5.0 cSt at the lowest temperature at which the carrier oil is used.

Using a carrier oil with the correct viscosity means the fluid has enough “thickness” to help the magnetic particles stay in suspension, while also being “thin” enough for the particles to move freely.

Unfortunately, not all products sold and used as carrier fluids meet the basic viscosity requirements outlined in ASTM E709, which may cause serious concerns if there is a quality issue or recall.

An NDT-approved carrier oil is virtually non-fluorescent, so it will not interfere with the detectability of fluorescent magnetic particle indications by adding background fluorescence.

Non-NDT-specific carrier oils usually fluoresce under UV light, which creates an automatic background on any part surface which makes indications harder to see and can even mask fine or small defects.

The carrier oil should have high flash point (above 200°F / 93.3°C). A high flash point improves operator and plant safety and helps prevent fires. OSHA typically requires a flash point at or above 200°F / 93.3°C for fluids that are used in open tanks.

Using a carrier oil with an OSHA-approved flash point is an easy way to safe guard yourself against fire and prevent operator injury, unnecessary downtime and costly equipment repairs or replacement.

The carrier oil should provide corrosion protection of most alloy parts and equipment components in magnetic particle testing machines. Proper corrosion protection protects the equipment investment and reduces maintenance and downtime.

While it is generally accepted that all oil-based products prevent corrosion, some non-NDT petroleum-based oils may contain ingredients or impurities which cause corrosion or hydrogen embrittlement over time. Only NDT-approved carrier fluids are tested and verified to safe-guard parts against corrosion.

The carrier oil should be a nonvolatile light petroleum distillate so it doesn’t evaporate easily. Not only does this mean there is very little odor from the carrier, but this also helps to extend bath life by protecting the magnetic particles.

With a nonvolatile carrier, operators are much more comfortable and proper bath concentration is easy to maintain because bath evaporation will be negligible.

Published February 27, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service