By David Geis, Product Manager

“Say what you do and do what you say.” That’s a quick way of describing how quality systems work. Processes are documented in procedures (Say what you do), and regular audits verify that those procedures are being followed (Do what you say).

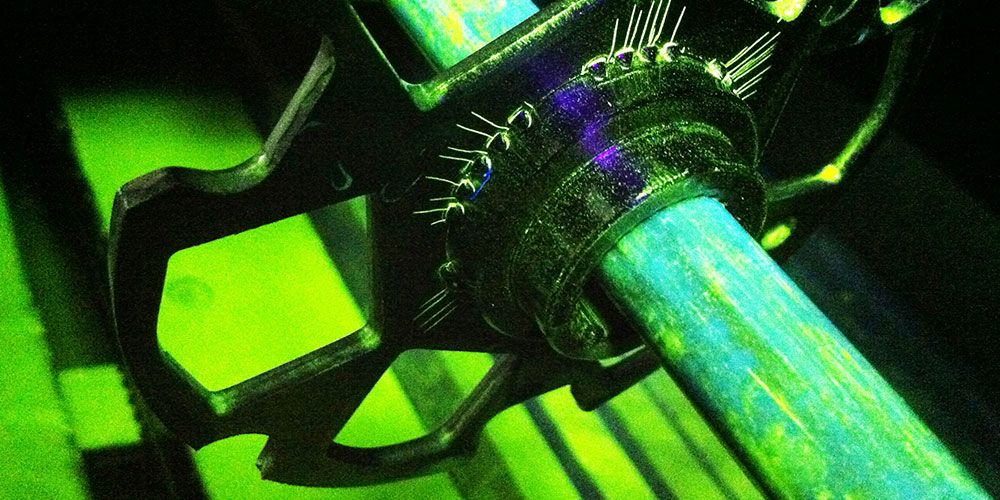

For Nadcap-accredited suppliers doing magnetic particle inspection (MPI), the second part can be the most difficult. Over the past year, the #1 non-conformance found by Nadcap auditors was demonstrating that parts were properly magnetized in accordance with the procedure or technique sheet. To demonstrate proper magnetization, first you need to know what’s in the procedure.

Written procedures for magnetic particle inspection must refer to the governing standard and must be approved by the responsible Level III. There are a lot of details required to spec out the full process, including part identification, materials used, process control checks, pre- and post-processing, and marking of parts after examination.

The technique sheet for a specific part must include the following information

These parameters will be different depending on the material, alloy, and geometry of the part being examined. It’s the responsibility of the Level III to make sure that all the details of magnetization have been defined, as well as making sure that the inspectors doing the actual examinations have the right training to do their job. Only then will you be able to demonstrate to an auditor that your parts are being properly magnetized.

Published December 11, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service