This highly versatile MD-2060 multi-directional magnetic particle inspection unit sets the standard for MPI inspection – saving you time in the process.

Password Protection: Setups are stored securely with our password protection system to ensure consistency and prevent accidental modifications.

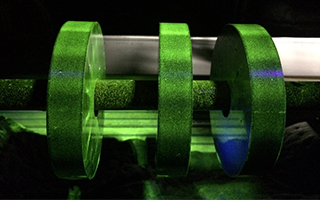

3 Outputs: You can select current types on three independently adjustable outputs to balance the magnetic field intensity – allowing you to process a wide variety of parts at different currents in half the time!

Mag Shot Timer: The adjustable Mag Shot Timer makes adjustments simple and easily accessible. Allowing the operator to set magnetization time from 0.5 to 2 seconds.

Double Mag Shot: While the Double Mag Shot enable button increases repeatability for better inspection quality.

Store Part Recipies: You can store up to 1,000 recipes for various parts. These recipes are easily recalled and allow you to store every detail from the current type to the power level.

Daily Reminders: For UV light, white light and bath concentration checks, improves inspection repeatability. Which are checked against pre-programmed acceptable measurements.

Auto-Bath: Other features include Auto-Bath which speeds up testing by automating the magnetizing process and automatically bathing the part.

Conveyor Inspcetion Booth: For maximum efficiency, our XG-Series conveyor inspection booth is designed for multiple operators, and is equipped with the S-1515 continuous duty demagnetizer.

UV Lamps: Our XG-Series hood enclosure features EV6000 hand held LED UV lamps that are instantly ready, with NO warm-up time – and have the widest beam on the market.

Advanced Reporting: When testing is complete, compiling data is quick and simple. Advanced reports are easily accessed and stored.

Warranty: Rely on our industry leading warranty with best in-class service delivered by a global network of trained Magnaflux authorized service centers. Warranty policy subject to change please see latest policy for details.

Please wait while we gather your results.

Related Blog Entries

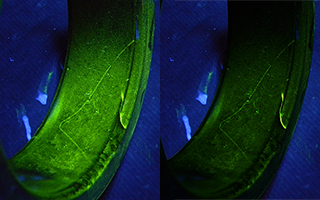

Watch a demonstration of the magnetic particle inspection method according to ASTM E1444 with basic steps for NDT using fluorescent magnetic particles.

Read More...

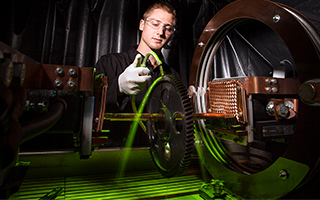

Watch the versatile MD-Series multi-directional mag particle inspection equipment in action. Learn how this wet bench can help you save time and money.

Read More...

Learn how to use M-Series magnetizing equipment to perform Magnetic Particle Inspections on a variety of large, heavy parts.

Read More...

Learn how this process-control and efficiency upgrade for mag particle testing helps NDT pros improve quality with less time.

Read More...

Watch a demonstration of the magnetic particle inspection method according to ASTM E1444 with basic steps for NDT using fluorescent magnetic particles.

Read More...

In this experiment, we compare the speed of a multi-directional magnetic particle wet bench to a traditional uni-directional method.

Read More...

![5 Things to Consider When Choosing a Mag Particle Yoke [Checklist] 5 Things to Consider When Choosing a Mag Particle Yoke [Checklist]](/Files/Images/Blog-Images/06042019-Titan-Thumbnail.png)

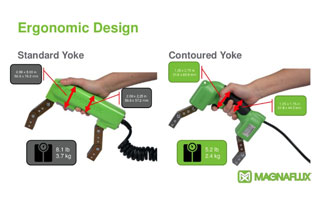

In this article we outline some key factors to consider when selecting the right electromagnetic yoke or contour probe for magnetic particle testing

Read More...

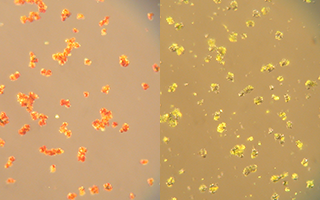

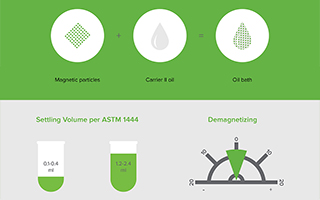

See how three common magnetic particle testing carriers perform in a standard ASTM E1444 settling volume test.

Read More...

To get a new wet bench or maintain the one you have? That is the debate. Learn the four most significant differences between Magnaflux wet benches developed in the 2000s.

Read More...

In this article, we list and explain why each Magnetic Particle Inspection accessory is needed to validate the system performance of an inspection

Read More...

This article discusses the most common incorrect assumptions about magnetic particle inspection and gives you some solutions to combat these misunderstandings

Read More...

See an overview of visible, dry-method magnetic particle inspection method according to ASTM E1444.

Read More...

In this article, we will go over the five key factors to successfully calibrate your Magnetic Particle Equipment in reference to ASTM E1444, ASTM E3024, ISO 9934, or Nadcap AC7114/2

Read More...

Breaking down the definitions of particle, micron, and the debate if magnetic particle size has an effect in magnetic particle inspection

Read More...

The next revision of ASTM E1444 is out for the final ballot, and a lot is changing. Here are five significant changes that you should know about for 2021.

Read More...

Understand the difference between magnetic particle inspection standards ASTM E709, ASTM E1444 and ASTM E3024

Read More...

How perception and vision can have a significant impact on probability of detection in non-destructive testing inspections.

Read More...

Learn how daily checks and maintenance can improve the lifespan of a yoke for a safer work environment

Read More...

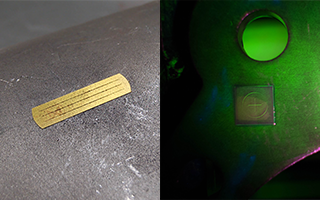

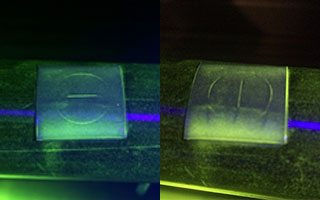

In this article, Magnetic Particle Inspection Flux Indicator Strips and Quantitative Quality Indicators (QQI) are defined and given a user manual approach to find artificial flaw standards

Read More...

We highlight the 5 major sections to understand on a Safety Data Sheets (SDS) in accordance with US OHSHA Hazcom 2012 GHS regulations

Read More...

Some handy tips for beginners who are new to magnetic particle testing or NDT pros who want an easy reference guide.

Read More...

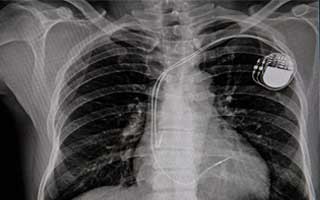

This article reviews the limitations of operators with cardiac pacemaker’s exposure to magnetic particle inspection equipment.

Read More...

Defining the different types of Level IIIs and some aspects of what their job entails

Read More...

Universal WE is a multi-directional wet bench designed to meet the speed requirements of high volume production facilities.

Read More...

Read how regular upkeep on mag particle equipment is critical for non-destructive testing to safe guard inspections & reduce downtime.

Read More...

Learn about multi-directional magnetization applications and how mag particle inspections can benefit from multi-vector magnetization.

Read More...

Explaining mag particle scenarios in the field, and how they can be changed depending on the yoke selection

Read More...

![What You Need to Start-up In-house Testing [Checklist] What You Need to Start-up In-house Testing [Checklist]](/Files/Images/Blog-Images/03162021-Titan-Thumbnail.jpg)

Step-by-step process listing everything from the equipment needed in magnetic particle testing and liquid penetrant testing to preparation for NDT audits

Read More...

Answering popular questions regarding shelf life for magnetic particle and liquid penetrant products used in nondestructive testing

Read More...

Secondary processing and finishing discontinuities are associated with the various finishing operations, after the part has been rough formed by rolling, forging, casting or welding.

Read More...

When steel ingots are worked down into usable sizes and shapes such as billets and forging blanks, some inherent discontinuities may appear.

Read More...

Service discontinuities are formed or produced after all fabrication has been completed and the part has gone into service.

Read More...

While one might assume defects or abnormities occur during a part’s manufacturing process, there are some discontinuities which occur before a part’s creation even starts.

Read More...

In the world of nondestructive testing, “defect” and its synonyms are not necessarily interchangeable.

Read More...

As the NDT industry continues to modernize and evolve in the 21st century, sustainability has become a hot topic. For suppliers and consumers of NDT products, evaluating and adjusting processes and products, investing in innovative technologies, and putting sustainability at the forefront are critical.

Read More...

This article explores issues many magnetic particle inspection operators face when testing diverse parts that require specific standards and acceptance criteria in a world that does not accept mistakes

Read More...

In this article, we explain what a P-Series portable power packs are capable of, and their next generation.

Read More...

![360° Sprayer on WCP-2 White Contrast Paint Aerosol [Video] 360° Sprayer on WCP-2 White Contrast Paint Aerosol [Video]](/Files/Images/Blog-Images/09182020-Titan-Thumbnail.jpg)

Apply our product at any angle with the upgraded 360° Sprayer on our WCP-2 White Contrast Paint and 7HF Magnetic Particle aerosol cans

Read More...

![Lightweight and Heavy Duty Magnetic Particle Inspection Yoke [New Product] Lightweight and Heavy Duty Magnetic Particle Inspection Yoke [New Product]](/Files/Images/Blog-Images/07252019-Titan-Thumbnail.jpg)

The Y-2 is an AC electromagnetic yoke for magnetic particle inspection that improves inspector productivity through a lightweight, ergonomic design. The Y-2 is the next generation of hand-held yokes that is more robust to survive harsh environments better than its predecessors.

Read More...

![5 Things to Consider When Choosing a Mag Particle Yoke [Checklist] 5 Things to Consider When Choosing a Mag Particle Yoke [Checklist]](/Files/Images/Blog-Images/07232019-Titan-Thumbnail.jpg)

Safety is a make-or-break factor in a technician's world – we list details around hazards, storage, recycling, and shipping of NDT aerosols

Read More...

In this article, we review the Nadcap requirements for proper magnetization and the importance of documentation for auditors

Read More...

A 4-minute mag particle primer to help you understand why this simple, quick, and effective method is still widely used today.

Read More...

This article explores a few of the approaches most Magnetic Particle Inspectors practice to check their system performance at regular intervals

Read More...

![Carrier II Comparison to Water Baths Effect on Mag Particle Wet Bench Lifespan [Case Study] Carrier II Comparison to Water Baths Effect on Mag Particle Wet Bench Lifespan [Case Study]](/Files/Images/Blog-Images/02252020-Titan-Thumbnail.jpg)

A brief overview of the 4 advantages of using a petroleum suspension vehicle bath to protect your magnetic particle wet bench investment.

Read More...

In this article, we explain what an NDT-approved carrier is and what sets it apart from commonly used, non-approved base oils

Read More...

Explaining the who, what, when, where, why, and how of Authorized Service Centers, and why they are best for NDT maintenance and repairs

Read More...

In this article, we explain why carrier oil is a critical part of the MPI process and which characteristics to look for when choosing an NDT carrier fluid

Read More...

In this article, we show two examples how Magnaflux can customize magnetic particle equipment

Read More...

Use the Universal WE ROI Calculator to learn how multi-directional magnetic particle equipment can save you time and money

Read More...

Understanding ASTM and SAE/AMS specifications to select the corresponding Magnaflux product for Liquid Penetrant and Magnetic Particle Inspections

Read More...

Learn about the most effective risk-reduction measure to increase safety for field inspectors

Read More...

In this case study, we help an aerospace MRO customer resolve fluctuations in their magnetic particle concentration

Read More...

According to ASTM E1444 and ASTM E3024 daily system performance checks are required. This article explains how to perform those checks.

Read More...

Learn about Magnaflux's NDT-approved petroleum base suspension vehicle for Wet Method Magnetic Particle Testing, and how it compares to competitors.

Read More...