By Arthur R. Lindgren, updated by Brian K. Batteiger, NDT Services Manager

While there are differences between industries, such as aerospace and automotive, almost every MPI inspector need to have a method in place for these tests.

Aerospace industry uses the AS-5282 Tool Steel Ring for their system performance check, which is typically done daily. The Tool Steel Ring is designed to produce a minimum number of indications at a specific amperage. With the large variety of parts tested by the aerospace industry, this is a good performance check on the health of the entire system. This includes:

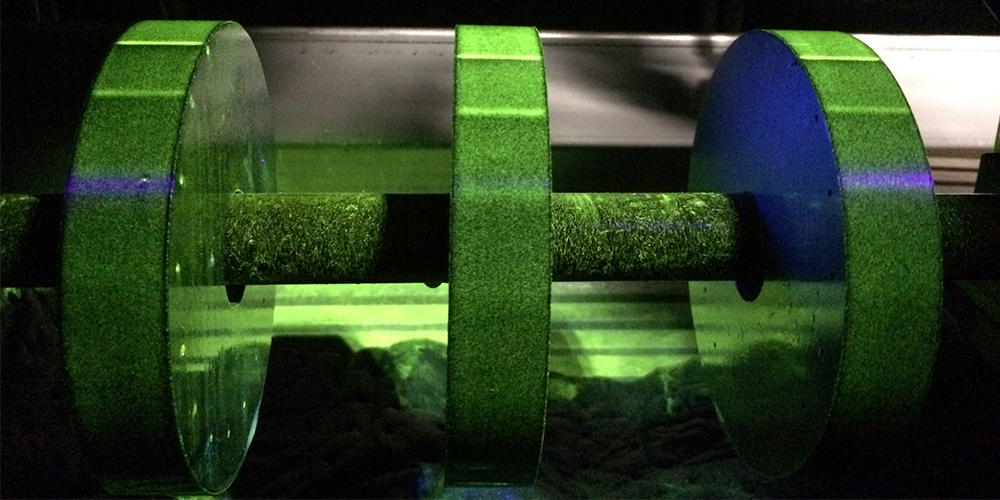

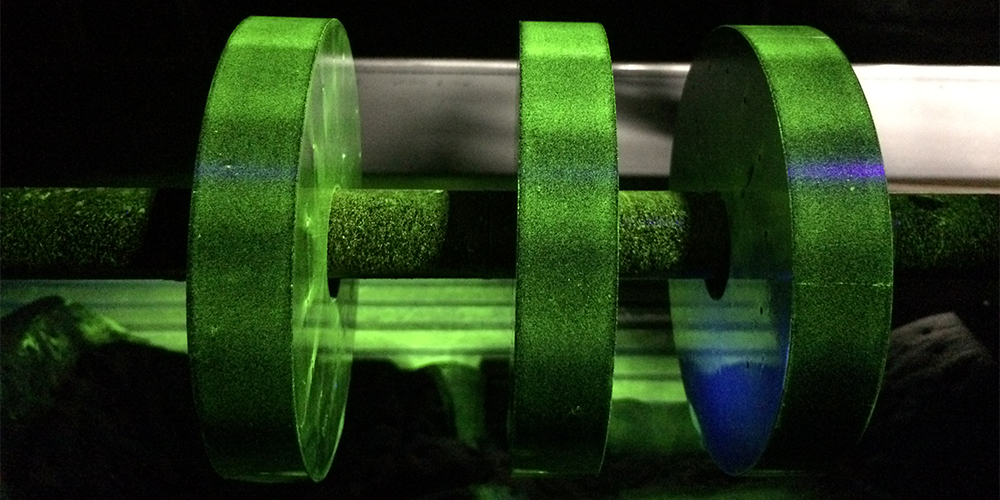

Tool Steel Ring at 500 Amps

Tool Steel Ring at 3,500 Amps

An option for some customers is to use a part with known defects. The problem with this option is “are your known defects a representative sample of all defects that could possibly occur?” When high volume of a given part is involved, an experienced inspector usually seeks out one or two parts, which have minimal size defects in those areas considered critical. He uses these parts to develop his MPI inspection technique.

Minimum, borderline, natural defects are difficult to find. Should a part have more than one critical area, his task is even more difficult. QQI’s are shims that have a specified artificial defect. These shims are not the perfect answer, but they are convenient and do work for most applications. They are the closest thing to having a large number of production parts containing defects of the type, location and size specified in acceptance requirements. By using a QQI shim at every critical location, only one sample part is required. This can become your “System Performance Sample.”

The “System Performance Sample”, may be used to determine how many shots are required and what current is best. Is multidirectional current magnetizing an option?

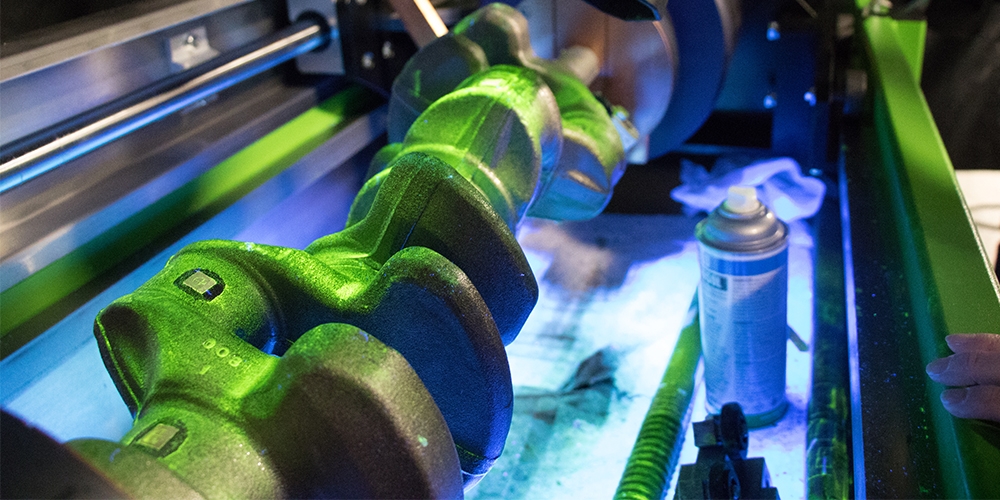

System Performance Sample Using QQIs

Developing the best inspection technique is important, but assuring it is consistently used is equally important. The inspector now has a part to run first, at the start of each production run, to assure that the complete “set-up” is in order. Are the bath concentration and bath application correct? Is the bath contaminated? Has the part been properly magnetized? Is there adequate black light and not too much visible light? Is the part being processed using the “continuous” method?

The argument still goes on questioning whether QQI’s or any paste on shim truly represent the actual natural defects being sought. The only true proof that a “System Performance Sample” using artificial defects is as good as one with natural defects is using it for set up and closely monitoring production line results.

Published May 8, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service