By Brian Batteiger, Service & Custom Equipment Manager

The latest editions of ASTM E1444 and ASTM E3024 require daily system performance verification of MPI machines. To perform this test, customers can either use test parts with discontinuities or fabricated test parts with discontinuities.

If using test parts with discontinuities, the reference parts should have discontinuities that are similar to the type, location and size specified in the acceptance requirements. It is also critical to demagnetize and clean the parts after performing the test to prevent false test results.

If customers are using fabricated test parts with artificial discontinuities, the discontinuity can either be the AS5371 notched shims or another type of flaw put into the part. The level 3 will determine the best method to use for this test.

With either method above, it is also critical to demagnetize the part and clean the part after completing the test. Demagnetization will prevent false results from residual magnetic fields and particles.

If performing a 100% inspection of your parts (in both the circular and longitudinal directions), the AS5371 notched shim (known as a QQI) provides an easy method of creating a test part to be used by various operators. Care must be taken to mark the part in such a way as it does not get mixed into regular production parts – which has been known to happen. All four edges of the AS5371 notched shim must be sealed using tape or super glue. Inspectors can also use the self-adhesive type of AS5371 Notched Shims.

When using the AS5371 notched shim (QQI) care must be taken when handling the part and it must not be touched. The AS5371 notched shim (QQI) are only .002” or .004” thick and t it will cause the notched to wear out and “disappear”.

|

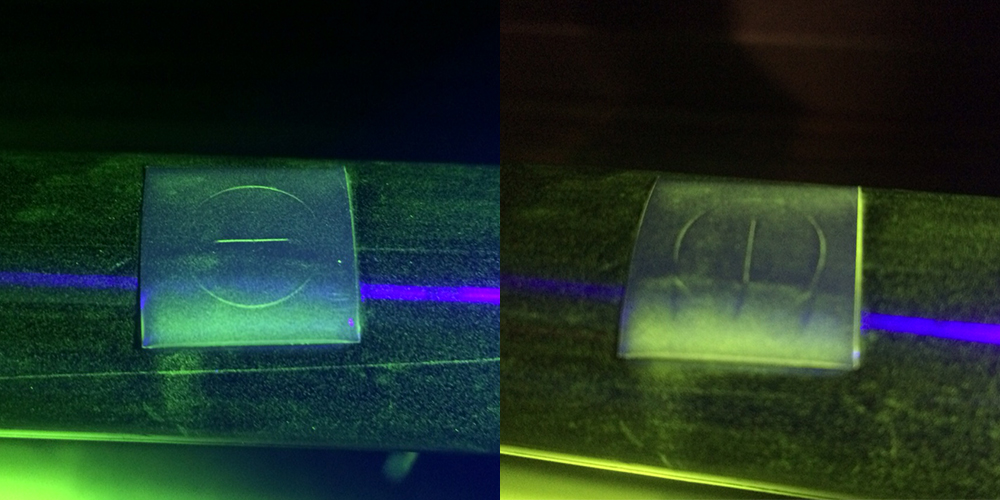

AS5371 Shim Circular Direction Note: The top of the circle, middle line, and bottom of the circle are of equal brightnesss |

AS5371 Shim Longitudinal Direction Note: The sides of the circle and the middle line are of equal brightnesss |

Magnaflux recommends that customers perform the system performance test once the pump has been running for 20 – 30 minutes and after the settling test is complete. For operation running 24/7 and maintaining settling test records, the system performance check can be performed when oncoming shift operators take over. Some operations perform the test at the beginning of the shift and after the operator comes back from the meal break. Performing the test multiple times provides a “window” of what parts they may have to retest should the test reveal issues.

The key to performing the system performance test is to know what results you are expecting; then if the results are different than expected, what are the possible causes of the poor results.

Below is a table for quick reference of some of the most common causes of poor results and the solutions:

|

|

Possible Cause |

Possible Solution |

|

Poor results in both circular and longitudinal directions |

1. Low particle concentration. 2. Contamination of bath (contamination mistaken for particles). 3. Improper agitation causing low particle concentration. 4. AS5371 notched shim (QQI) 5. Machine malfunction |

1. Add particles. 2. Replace bath (and clean the tank). 3. Fix agitation (typically filter screen needs cleaning) 4. Replace AS5371 notched shim (QQI) 5. Machine repair |

|

Poor results in circular (contact) direction only |

1. Worn copper pads 2. Worn lead plates or lead plates, not making good contact. 3. AS5371 notched shim (QQI) 4. Corrosion on copper pads and lead plates (especially water bath users) 5. Machine malfunction |

1. Reverse or replace copper pads 2. Replace lead plates and ensure they are making good contact with copper plate. 3. Replace AS5371 notched shim (QQI) 4. Clean off corrosion/Replace copper pads and lead plates if necessary. 4. Machine repair |

|

Poor results in longitudinal direction only |

1. AS5371 notched shim (QQI) 2. 4/0 cables 3. Failed coil 4. Machine malfunction |

1. Replace AS5371 notched shim (QQI) 2. Replace 4/0 cables 3. Replace coil 4. Machine repair |

Published August 6, 2019

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service