By David Geis, Product Manager

In both the Penetrant and Magnetic Particle checklists, Nadcap requires UV-A lamps to be checked for visible emission at 15 in / 38 cm using a standard light meter. Frequently, readings are above 2 foot-candles / 20 lux, and the conclusion is there’s something wrong with the lamp. However, the process of identifying the root cause is not that simple.

The requirement for checking visible light emission from UV-A lamps traces back 25-30 years. At the time, there was only one type of inspection lamp – mercury vapor – but there were a couple of different configurations. The standard 100W lamp required a separate “woods glass” filter to block out visible light and only transmit UV-A. By far, this was the most common lamp in use, but it was not the only one available. 125W self-filtered bulbs offered high intensity and the bulb itself was “woods glass” to filter out visible light. The problem was the bulb glass was too thin to block all the visible light.

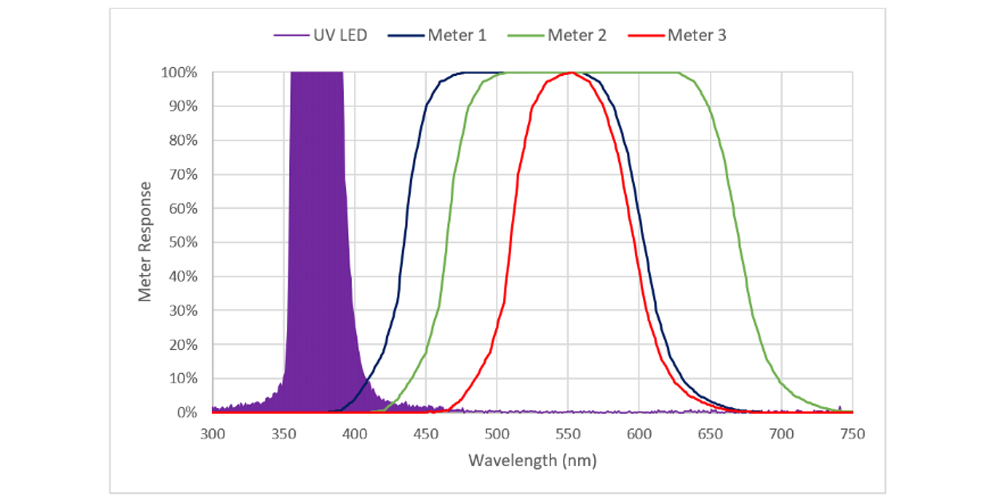

In response, aerospace primes created a new requirement: if you were using a 125W lamp, you had to check the visible light emission to maintain the dark inspection area below 2 foot-candles / 20 lux. A simple solution, but there was some complexity involved – different light meters would give widely different results. That’s because the reading you get from a standard light meter depends on the filters used to tailor its response curve, and different manufacturers use different filter stacks. Typically that variation isn’t a problem when measuring a white light source, but not so with UV-A sources. Inspection lamps are very intense, and the filter stack in the light meter must block all UV energy and only pass the tiny amount of visible light remaining. Optical filters are not 100% effective, so the meter reading depends more on the exact types and tolerances of the filter stack than it does on the source itself. To solve this technical difficulty, aerospace primes included a table of approved light meters and the maximum acceptable reading for each one. The acceptable readings varied widely, from 0.3 to 8 FC or 3 to 86 lx depending on the light meter.

In time, this aerospace prime requirement was included in Nadcap checklists, but there were a few modifications:

Standard 100W mercury vapor lamps produced a very sharp peak at 365 nm, so there were seldom any problems with visible light emission. But LED lamps changed things.

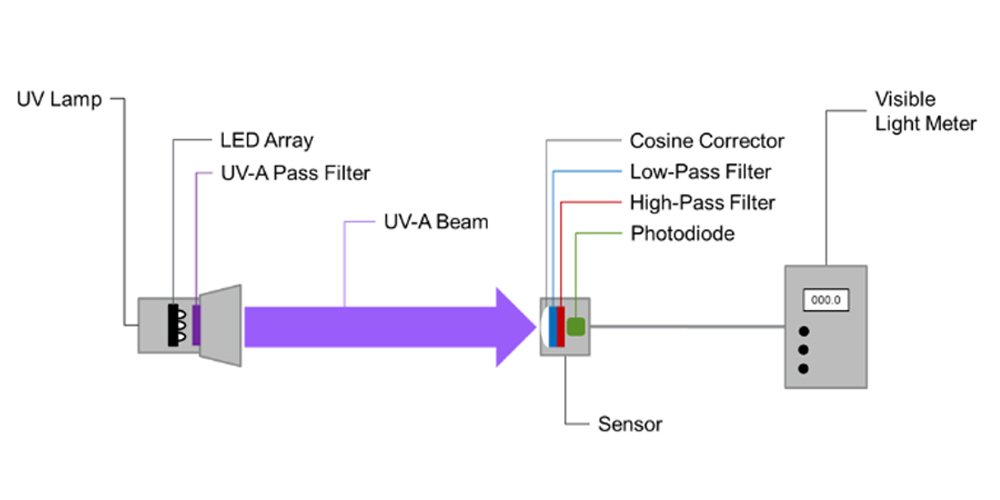

UV-A LEDs have a broader emission spectrum, including a small amount of visible light, which can be observed as a deep violet glare. To eliminate that glare, ASTM E3022 requires that inspection lamps include a UV-A Pass filter to block visible emission. Learn about the function and importance of UV-A pass filters, and why ASTM E3022 requires all LED UV lamps to have them here. Even so, many operators still get readings above 2 FC / 20 lx with their standard light meters, and that continues to be a problem.

Ultimately, the answer is that standard light meters are not able to accurately measure the small visible light emissions from a high-intensity UV-A source. LED lamp manufacturers use spectroradiometers to calculate the visible emissions from each lamp during ASTM E3022 certification. With standard light meters, the filter stacks and tolerances vary from model to model and from manufacturer to manufacturer. That means different light meters give you different readings from the same LED lamp, dependent on each meter’s response curve. While it didn’t make much difference with old mercury vapor lamps, it does make a difference with the broader emission spectrum of UV-A LEDs.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service