By David Geis, Product Manager

The user-check requirements for LED UV-A Lamps continue to evolve as Aerospace Primes have more experience and feedback from their supplier network. Previously, we described How to Check LED UV Stability in order to comply with Airbus AITM 6-1001 Issue 11. Since then, Airbus has changed the monitoring requirements for users. LED UV Stability is no longer a monthly user check, however new and different user checks are required. Here’s what you need to know.

Per Airbus Memorandum ME1720084, four monthly checks are required for all LED lamps used for inspection: Beam Variability, Minimum Working Distance, Beam Irradiance Profile, and Maximum Irradiance. The results of these four checks must be recorded in a written report. Some of these will be familiar, but until now the others have only applied to lamp manufacturers.

Checking the Maximum Irradiance is the same as a normal UV-A lamp intensity check. The lamp is held at a fixed distance from the UV-A meter and the irradiance is verified in µW/cm2. For Airbus, this check is performed at the individual lamp working distance. As part of Airbus and Rolls-Royce certification, lamp manufacturers will verify the working distance of each individual lamp for a maximum irradiance of 5,000 µW/cm2, and the result is listed on the lamp certification. That working distance should be used in place of the standard 15 in / 38 cm distance to comply with the latest Airbus requirements.

Most UV-A lamps on the market are set to provide 5,000 µW/cm2 at a distance of 15 in / 38 cm. Learn what’s so special about those numbers here.

The Beam Variability can be verified during a regular “White Paper” check. The lamp is held at a distance from a large sheet of white paper, and the beam is observed. There should be no obvious intensity fluctuations, flicker or strobing, just as there should not be any obvious bright or dim spots within the beam. Note that this is a subjective check and is recorded as either acceptable or unacceptable. Photo documentation is not required.

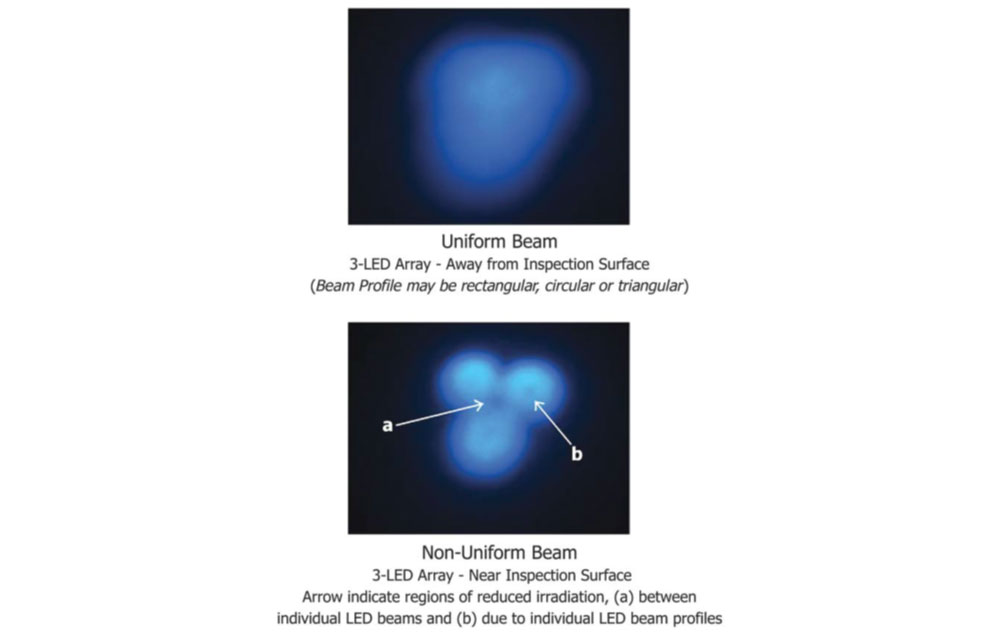

The other two monthly checks are new for users. The procedures are given in ASTM E3022, which is a specification intended for lamp manufacturers. Per E3022, the Minimum Working Distance is the shortest distance the lamp can be used before the beam is not uniform. Thankfully, it can be easily verified during a regular “White Paper” check. After checking the Beam Variability above, slowly move the lamp closer to the white paper until the beam pattern exhibits a visible non-uniformity, or individual LEDs become distinct. The distance where the beam is obviously non-uniform is recorded as the Minimum Working Distance. To fully comply with Airbus requirements, the maximum intensity of 5,000 µW/cm2 will likely be reached before the Minimum Working Distance per E3022.

Learn what to consider when looking for a new UV-A light for fluorescent penetrant testing or magnetic particle inspection here.

ASTM E3022, FIG. 2

Example of Uniform and Non-Uniform Projected Beams

for Determining Minimum Working Distance

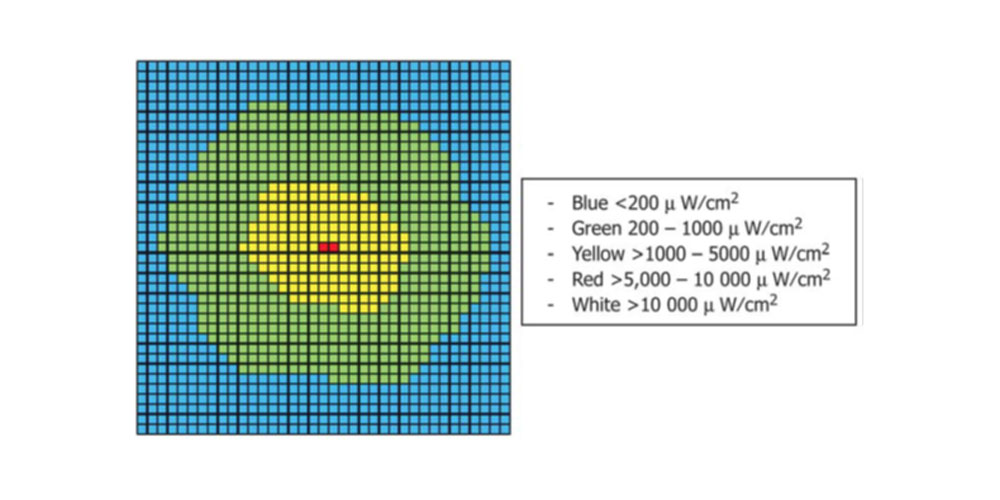

The last monthly check is the Beam Irradiance Profile. While the previous user checks can be done easily with minor changes to procedures already in place, verifying the beam profile of an LED lamp is far more involved. A detailed procedure can be found in E3022 Section 7.4, and Airbus has specified a few changes as well.

Mount the lamp above a flat workbench at the individual lamp working distance (with 5000 µW/cm2 maximum intensity from the individual lamp certification).

Turn on the lamp and allow it to stabilize. E3022 specifies at least 30 minutes before taking any measurements.

Use a calibrated UV-A radiometer to find the maximum irradiance at the center of the beam and record the intensity.

Starting from the center as a zero-point, move the UV-A sensor laterally and record the intensity using an 0.5 in / 13 mm grid, mapping the full beam profile until the intensity drops below 200 µW/cm2.

Using this data, create a 2-D plot of the beam irradiance, and report the diameter of the beam at 1000 µW/cm2 and 200 µW/cm2.

For hand-held lamps, the diameter at 1000 µW/cm2 must be at least 5 in / 127 mm.

ASTM E3022, FIG. 1

Example of Beam Irradiance Profile

Mapping the Beam Irradiance Profile requires a dedicated fixture to mount the lamp and hold it steady while measurements are taken. It’s very important to use a fixture to hold the lamp in place for the full test. That’s because UV-A intensity follows the inverse-square law, so any small changes in the distance to the UV-A meter are multiplied and will skew the results. Mapping the Beam Irradiance Profile also takes time. Just for the minimum 5 in / 127 mm beam diameter, the 2-D map requires at least 170 separate measurements. The full Beam Irradiance Profile out to 200 µW/cm2 can mean 4 times as much data and hours of labor. This check cannot be done while manually holding the lamp.

The changes Airbus has implemented with Memorandum ME1720084 will be incorporated into Issue 12 of AITM6-1001.

Published November 5, 2018

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service