January 30, 2018 | by David Geis, Product Manager

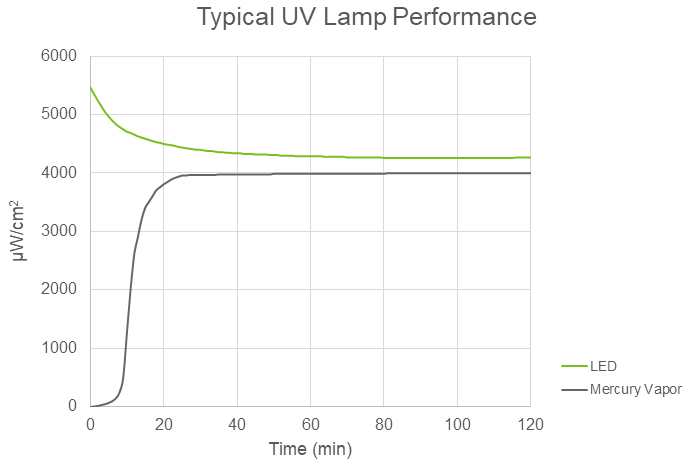

One advantage to LED UV lamps is they are at full intensity from the instant they are turned on, unlike traditional mercury vapor black lights which require 10-15 minutes to get up to full intensity. So it can be confusing when the product data sheet for an LED UV lamp lists a “stabilization” time. How can the LED lamp be instant-on but still need time to stabilize?

To answer that, we have get into the details of how different lamps work.

With a traditional mercury vapor lamp, light is generated from a high voltage arc through vaporized mercury within the bulb. When the lamp is turned on, a starter circuit generates heat inside the bulb which vaporizes mercury within the bulb until there’s enough to strike the main arc through the vapor.

It takes about 10-15 minutes to get enough mercury vapor inside the bulb to produce full intensity. That’s where the “warm-up” time for a traditional mercury-vapor lamp comes from: the bulb literally needs to warm up to generate light.

LED’s have an opposite response. An LED is a semiconductor chip that emits light when current is passed through it. In general, semiconductors are more efficient when they are cold, so an LED has maximum efficiency (i.e. puts out the most light) when the lamp is first powered up.

The flow of current through the LED chip warms it up, which reduces the efficiency. Which means that as an LED light is used, the amount of light it generates will go down. To manage this effect, LED lamps are designed to move heat away from the LED chips until the overall temperature stabilizes.

That’s why LED lamps have a “stabilization” time instead of a “warm-up” time: the intensity will drop until the temperature stabilizes. But it’s important to realize that LED efficiency works both ways: turning off an LED lamp will let the LED chips cool down, and their efficiency will go back up. So the LED UV lamp will be back up to its maximum intensity the next time it’s turned on.

ASTM E3022 requires lamp manufacturers to characterize the stabilization time for LED lamps. Stable operation is defined as not more than 5% variance over 3 different measurements taken 30 minutes apart.

For example, a stabilization time of 5 minutes means the intensity will decrease during the first 5 minutes of operation, but after that it will remain stable within +/-5%.

By understanding of the difference between “warm-up” and “stabilization” times explains why a tech sheet for an LED UV lamp will include information on stabilization time. Mercury-vapor ultra-violet lamps need to physically warm up to get up to full intensity whereas LED lights have full intensity immediately when powered on, but intensity will decrease slightly until the temperature stabilizes.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service