September 18, 2017 | by Emily Gibbons, Marketing Manager

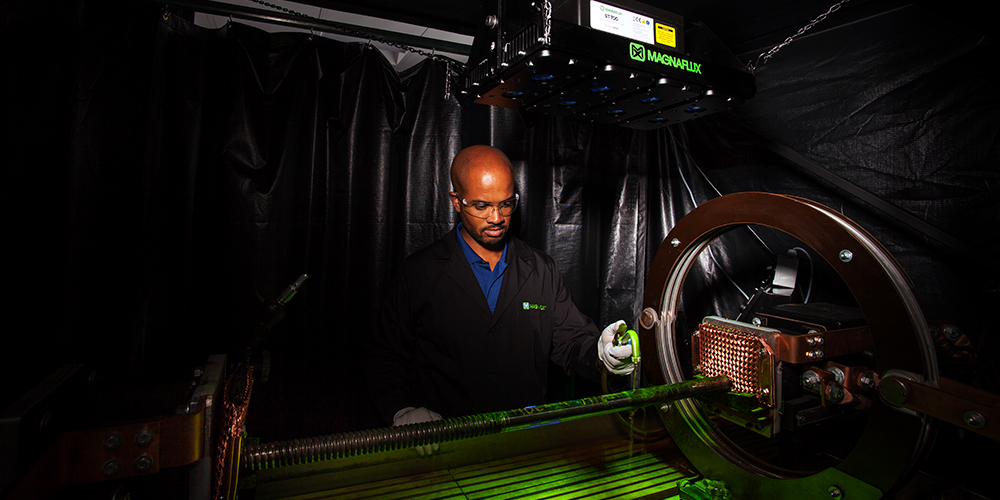

After consulting with numerous NDT experts and inspectors, Magnaflux is expanding their line of LED UV lamps for non-destructive testing with the ST700 overhead inspection LED UV light, which is specifically designed to eliminate or prevent some of the most common challenges around UV illumination in fluorescent NDT testing.

“Customers using fluorescent or mercury-vapor solutions today find that they do not have the coverage or intensity that they need to properly and efficiently inspect their parts. They also have to deal with frequent bulb failures, hazardous waste disposal costs, and the swift disappearance of mercury vapor bulb replacements in the market. On the other hand, current LED solutions are often too fragile to stand up to harsh industrial environments, while still not providing the coverage that they require,” explains Sakif Ferdous, Magnaflux Market Research Manager.

Designed and tested by NDT professionals, the ST700 speeds up fluorescent NDT processes while also improving inspection quality with an ultra-wide, 12 x 24 in / 30 x 61 cm UV-A beam when mounted 39 in / 1 m from the inspection surface.

The ST700’s best-in-industry UV-A inspection area allows inspectors to quickly examine parts while minimizing part handling, especially with larger test parts, and the high intensity UV illumination helps indications stand out bright and clear for faster detection.

“The Magnaflux ST700 LED blacklight provides brighter UV light, runs cooler, uses less energy, and eliminates the disposing of hazardous mercury bulbs. It is very reliable and well suited to use in a fixed location. We use our ST700 24 hours a day with 100% confidence,” says Joseph A. Michel, NDT Level 3 and Met/Chem Lab Business Manager at UTC Aerospace Systems.

The ST700 offers the best beam-area value of any stationary flood LED UV lamp on the market with a maximum inspection area of 22 x 25 in / 55 x 64 cm with UV-A over 1,000 μW/cm2. This ultra-wide beam meets ASTM and RRES requirements for UV-A illumination so inspectors can be confident to see every indication with less part handling.

“The extra-wide beam shows more area at once, and smooth, even coverage means you don’t have to keep repositioning the part,” continued Geis. “All of which lets you get the job done faster.” During field evaluations, our beta-testers found the ST700 beam is wide enough to cover large cast parts without additional part handling.

Providing 7,000 μW/cm2 of high intensity UV-A light at 15 in / 38 cm, the ST700 makes fluorescent penetrant and magnetic particles stand out bright and clear for high-contrast visibility and easy detection. The high intensity LEDs allow the ST700 to be mounted up to 36 in / 90 cm from the inspection surface and still maintain UV-A over 1,000 μW/cm2.

“We consistently get around 4,000 μW/cm2 at a distance of 24 inches, which is at our part surface,” said one ST700 beta tester.

Another beta tester stated, “The (ST700) light emits the proper frequency, same as the old mercury vapor bulbs, which makes the indications fluoresce better.”

The ST700’s LED array is designed to cast uniformly bright illumination, and the stable intensity of the LEDs meets the ASTM E3022 and Rolls-Royce RRES 90061 standards. The custom UV-A filters reduce glare and increase fluorescent contrast to make indications easier to see.

“Glare from the lamp reduces contrast on the surface you’re inspecting, and that slows down the inspection process,” added Geis. “The ST700 includes filters to eliminate violet glare and each unit is certified to all the latest aerospace specs.”

Engineered specifically for the rigors of NDT and manufacturing environments in order to reduce on-the-job downtime, this stationary floor UV light is fully sealed to prevent dust or water damage. The dependable, impact-resistant construction, along with the fan-less cooling system and proprietary, non-clouding LED lens provide reliable, consistent inspections.

"Magnaflux designs equipment with the real world in mind, and that reliability is what you need for consistent results in critical inspections,” explains Geis. ST700 beta testers liked the simplicity of the light, noting there are no fans or filters to clog up, and no loose control remote to misplace.

With LED technology, the ST700 runs much cooler than traditional mercury-vapor lamps to help keep operators and inspection booths cool. "Fluorescent inspection is highly technical, requires concentration and intense focus,” points out Geis.

“Our operators appreciate the light not dumping additional heat into the booth, and our safety engineers love it because it has no mercury, uses less energy, and has a bright white-light mode,” said a beta-tester.

Learn more about the new ST700 overhead inspection UV lamp for NDT, including additional benefits and technical specifications. Ready to place an order? Contact us to place an order or find a distributor.

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service