By David Geis, Accessory Product Manager

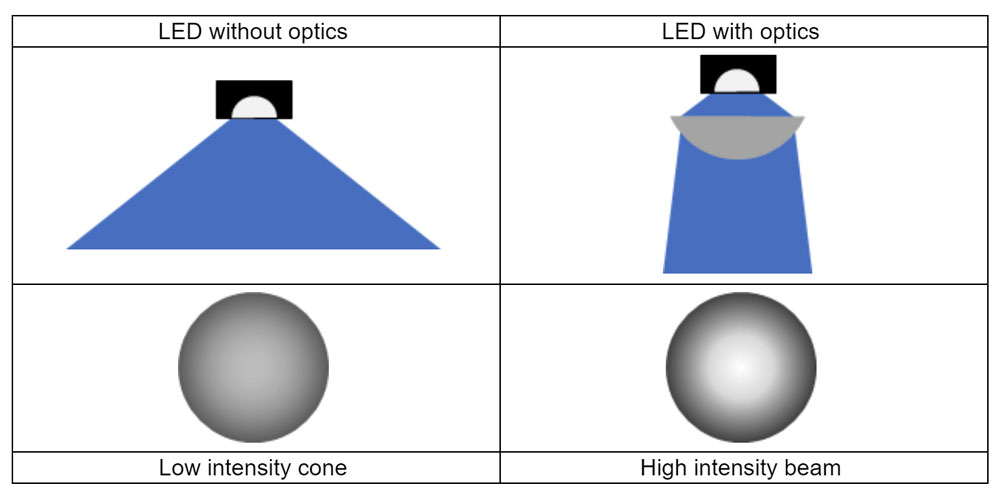

An LED by itself, without optics, emits light in all directions. That may sound like a favorable property because it means an LED will light up a wide beam. However, the problem for NDT inspection with this type of LED is that you don’t get much intensity at any one spot. That’s acceptable for background illumination, but for inspection you need to meet minimum intensity limits set by standards committees.

LED Optics are the solution – the optics focus the LED light into a usable more concentrated beam. For a UV LED lamp to be useful for NDT for inspection, there needs be an optic over the LED source to provide a useful intensity.

By reviewing the illustration, it is apparent that there is a design trade-off involved. Wide-angle beams provide smooth and even profiles, but narrow-beams provide the intensity needed for fluorescent inspection. A well-designed LED inspection lamp needs both for the best results.

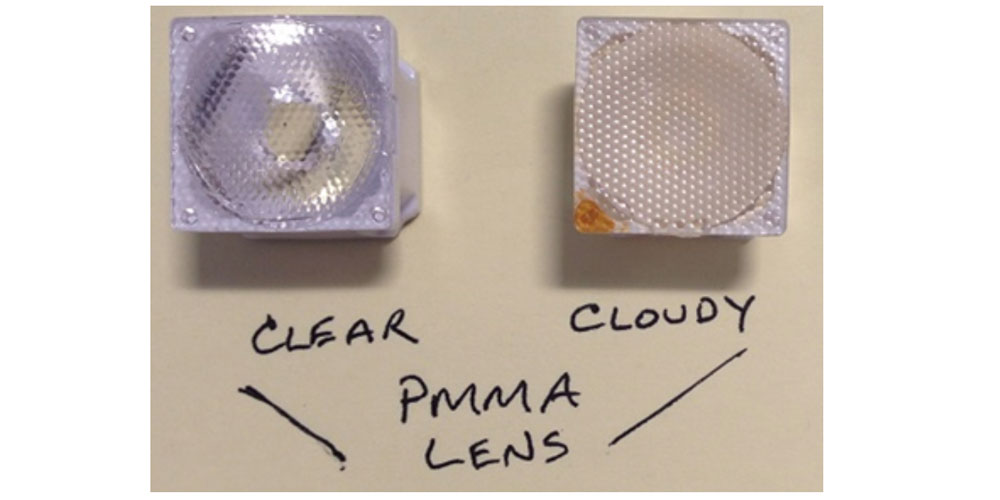

UV-A LEDs present an extra challenge for optics. Common LED optics are made from PMMA (acrylic) – it’s cheap, easily molded into the required shape, and transparent for visible light. However, PMMA absorbs UV and will solarize (yellow and cloud over). The same phenomenon can be seen in older automotive headlights - with exposure to the UV from the sun the clear plastic becomes cloudy.

With the special treatment optics will still solarize over time. Solarized lenses will severely decrease the output of an LED lamp, and that’s why low-cost UV LED lamps needed replacements on a regular basis.

Lamp manufacturers need to balance all these factors into the design of an inspection lamp that (A) has a useful intensity, (B) has a beam with a smooth and even profile without hot spots, and (C) is long-lasting and durable.

With the EV6000, Magnaflux developed custom LED optics made from UV stable material. That means the lenses will not solarize and the UV-A intensity will not degrade over time. All LED UV-A Lamps from Magnaflux use these custom optics for dependable performance and a long life.

Published March 5, 2019

JOIN OUR MAILING LIST TO RECEIVE THE LATEST NDT INSIGHTS AND ARTICLES FROM MAGNAFLUX

The Magnaflux team is happy to assist you with your nondestructive testing needs. Please opt-in to Tracking cookies to use the contact form by clicking Cookie Settings and updating your preferences to complete our contact form. If you do not wish to opt in, you can connect with us at support@magnaflux.com or call us at +1-847-657-5300

155 Harlem Avenue

Glenview, IL 60025, USA

Telephone: +1 847-657-5300

Contact Magnaflux Customer Service